Pipeline cleaning system for paint factories

Having an automated pipeline cleaning system in paint and paint-related product factories can be decisive in optimising production processes and achieving greater profitability. Besides, it is also environmentally friendly.

At Oliver + Batlle, we have developed a pipeline cleaning system for paint and paint-related product factories that collects residual content stuck inside the pipe while cleaning it. Known as Pigging System, it is a complement for industrial automation offering many advantages.

This article explains step by step how it works and what the most significant advantages are for your manufacturing plant.

Pipeline cleaning automation

The classic pipeline cleaning system in paint and paint-related product factories requires the manual handling and cleaning of numerous pipes, which implies great issues, such as:

- the cross-contamination among products transferred through the same pipe,

- the pipeline cleaning time, which may affect the manufacturing cycle,

- the need for extra space to clean the pipes,

- the high risk of bacterial contamination,

- the considerable amounts of residual product that remain inside the pipeline and need to be cleaned out, due to an insufficient suction when the line is emptied and the consequent inability to pump,

- the need for specific cleaning products,

- the process’s environmental impact, due to the waste generated and the products required to carry out the cleaning.

At Oliver + Batlle, driven by our eagerness to offer efficient solutions to the paint and paint-related industry, we have developed a pipeline cleaning and emptying system that solves these problems, bringing with it great advantages to the production process.

Our automated pipeline cleaning system, Pigging System, which has been entirely developed by our engineering department, is the result of the innovation and development capacity of a team and a company with over 60 years’ experience in the industry. Let’s see how it works.

Pipeline pigging installations

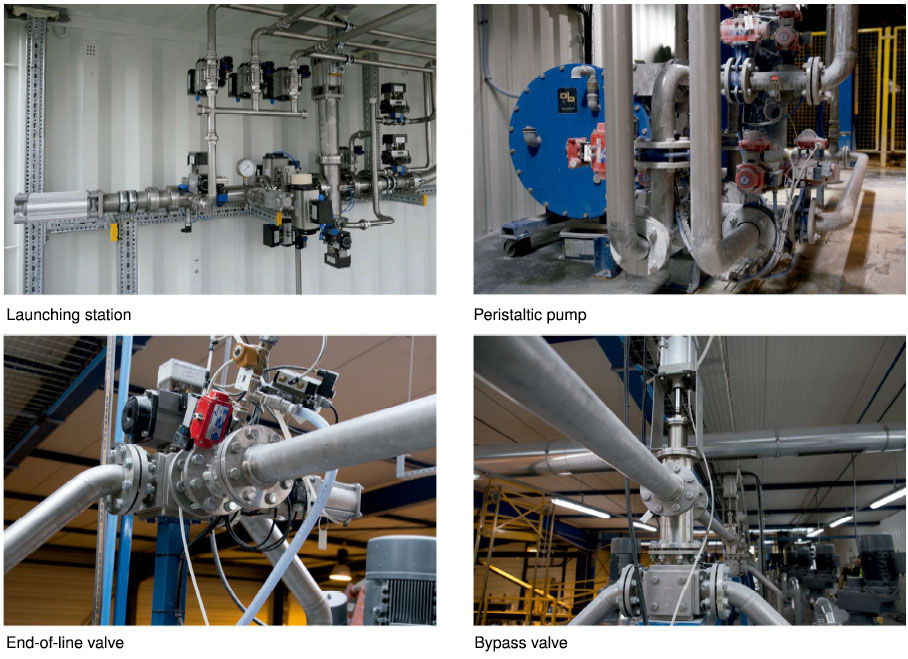

O+B has been integrating the pipeline cleaning system, Pigging System, in its turnkey projects for many years. This type of installation, particularly suitable for high-performance paint filling lines with automated format changeover, can be adapted to all kinds of manufacturing plants.

The main fields to which our comprehensive pipeline cleaning system can be applied are:

- transfer lines between process, dilution and storage tanks,

- filling lines,

- transfer of major raw materials (emulsions, resins and solvents) from their storage points to the process tanks,

- transfer of minor raw materials (additives) to the weighing hopper.

How does it work?

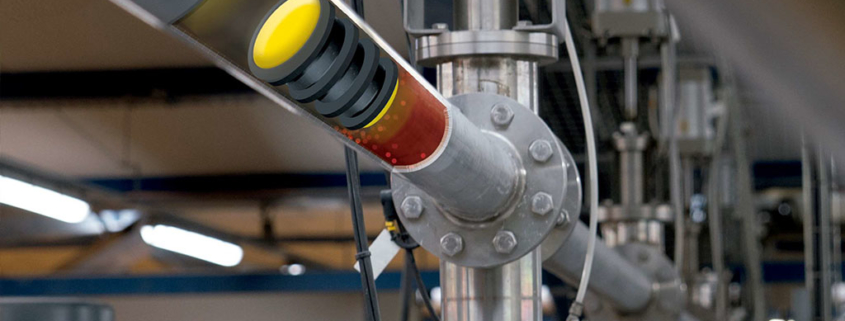

Pigging System is mainly used to clean the pipelines through which different products are transferred. This cleaning system consists of the implementation of a technology that uses a ‘scraper’ (PIG) to remove any residual product from inside the industrial pipeline, cleaning it completely.

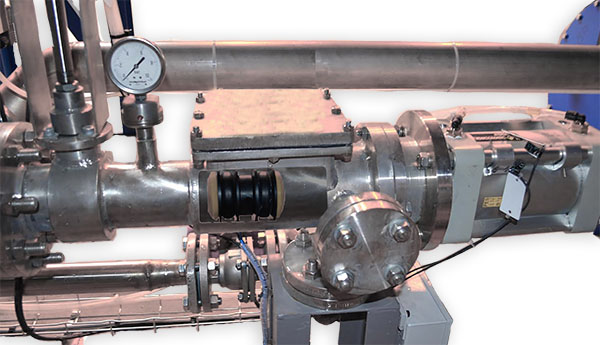

The full pipeline cleaning system consists of the following components:

- pigging system pipelines in accordance with DIN 2430-1 standard (DN40 to DN125),

- PIG or ‘scraper’ comprising different materials and designs depending on the application,

- specific station to launch and receive the PIG or scraper,

- one-way and two-way intermediate valves with no retention area (no product accumulation),

- volumetric pump (in case of liquid) or air/N2 system (in case of gas),

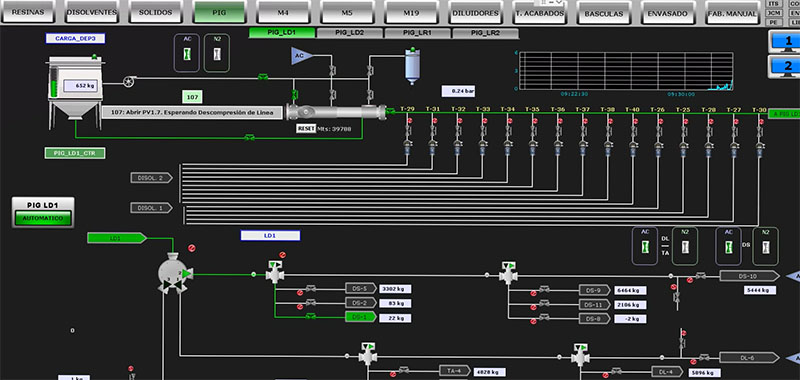

- control system or software integrated in an existing system already installed by O+B, or in a high-performance filling line.

All these components have been manufactured by O+B, which offers a comprehensive guarantee and customisation for each part, adapting them to each manufacturer’s needs. Besides, it makes it possible not to depend on third parties when implementing a Pigging System in the factory, or in case technical assistance and maintenance of the installations are required.

Depending on the installations and the type of product being manufactured and its viscosity, the PIG or ‘scraper’ can be cylindrical, with discs or with replaceable discs. They can be made of FKM, EPDM, silicone, vulkollan… And they can reach a speed inside the pipelines of between 0.2 and 1 m/s.

Pipeline cleaning process in paint and paint-related product factories

Below, the pipeline cleaning process that the Pigging System performs is explained. The transfer from processing equipment, or finishing tank, to a paint filling line is used as an example:

- First step: transfer paint A, for example, white, from the storage tank to the filling line.

- Once the paint A storage tank has been emptied and the valves are closed, the water valve opens and the volumetric pump starts to operate (if the system uses liquid as its drive media).

- The PIG is launched from the launching station, driven by the liquid, completely emptying and cleaning the pipeline.

- The PIG reaches the filling unit hopper and the filling unit cleaning cycle starts.

- The system itself cleans the PIG which, once cleaned, returns to its initial position driven by air.

- The volumetric pump turns off and the water valve closes.

Once the process finishes, it is possible to start the transfer from paint B tank, which is red, for example. The pigging system makes it possible for the new product’s filling process to be carried out with no contamination (the red paint is not contaminated by the white paint).

Furthermore, as the system is completely closed, the risk of bacterial contamination is reduced, resulting in a hygienic and effective pipeline cleaning technology.

Finally, it should be noted that, its integrated control software makes it possible for the operator to monitor and control the pipeline cleaning process within the manufacturing plant at all times.

A sustainable pipeline cleaning system

The implementation of the pipeline cleaning system, Pigging System, for paint and paint-related product factories offers a series of benefits that contribute to a more profitable and sustainable production process:

- Space saving. The pigging system simplifies the installation by replacing numerous transfer pipelines with a single line or just a few lines. This results in more compact and rationalised installations.

- Time reduction. The cleaning and maintenance time between two production batches are reduced, ensuring a standard quality in the cleaning process and extreme colour changes. This improves the production process and makes it more flexible.

- Cost reduction. In this regard, the following stand out:

- Savings in installation costs, as fewer pipelines are required.

- Cost reduction in wastewater treatment or cleaning solvents, as a less amount of them is required.

- Reduction in generated shrinkage costs, as the entire product is used.

- Reduction in manufacturing downtime costs for pipeline cleaning processes (emptying and cleaning with thinner or water).

- Fast return on the investment made in the pigging installation.

- Environmentally friendly. The integrated cleaning system reduces waste generation to a minimum. Besides, the required amount of cleaning liquid is considerably reduced. This system minimises environmental risks in paint and paint-related product manufacturing plants.

At Oliver + Batlle, we would like you to request more information about our automated pipeline cleaning system and to visit our pilot testing station located in Badalona. Write to us through our ‘contact’ section. Check out all our latest news on our LinkedIn profile.