EQUIPOS DE AGITACIÓN PARA EL SECTOR COSMÉTICO

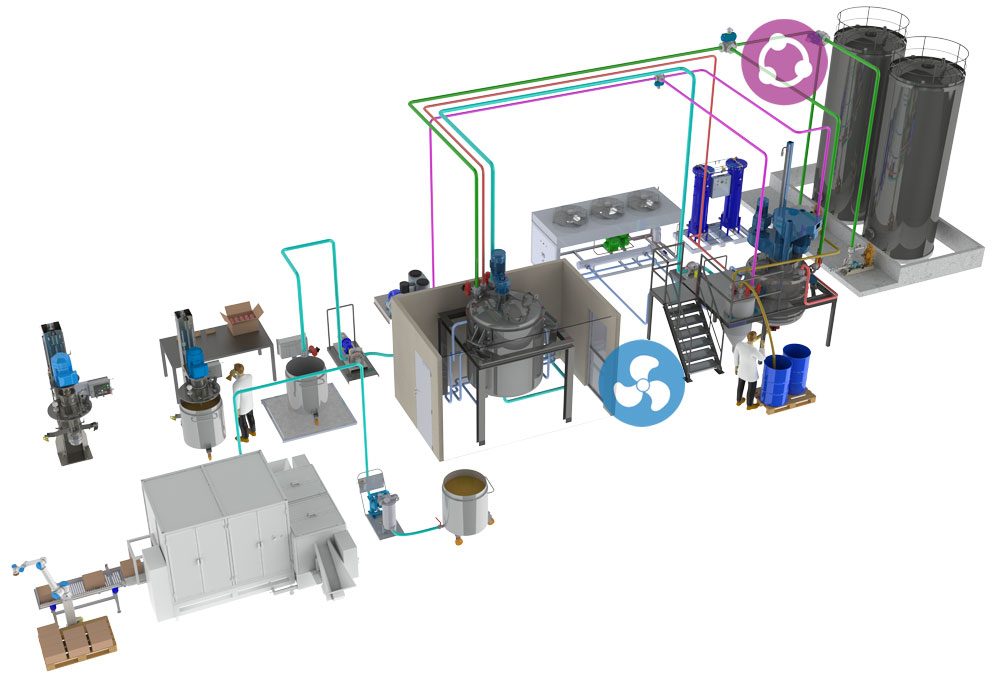

Las soluciones de agitación de O+B para el sector cosmético ofrecen una gran adaptabilidad a todo tipo de productos y viscosidades.

Ofrecemos una amplia gama de opcionales y discos de agitación: tapas de vacío, telescópicas, palas rascadoras u orbitales, discos radiales, radial-axiales o mezcladores, etcétera.

Nuestros equipos están diseñados para la fabricación de grandes lotes, para mayoristas del sector cosmético o para la fabricación de bases, ofreciendo una gran robustez y un acabado de alta calidad.

Además, le ofrecemos la capacidad de incorporar automatismos para la incorporación de materias primas mediante la gestión por pantalla táctil con un software de desarrollo propio. Con ello podrá realizar el transporte automático de todo tipo de materiales: sólidos, líquidos y gases. También ponemos a su disposición Dispervac, un sistema avanzado de carga de sólidos por vacío directamente a través del fondo del depósito de producción.