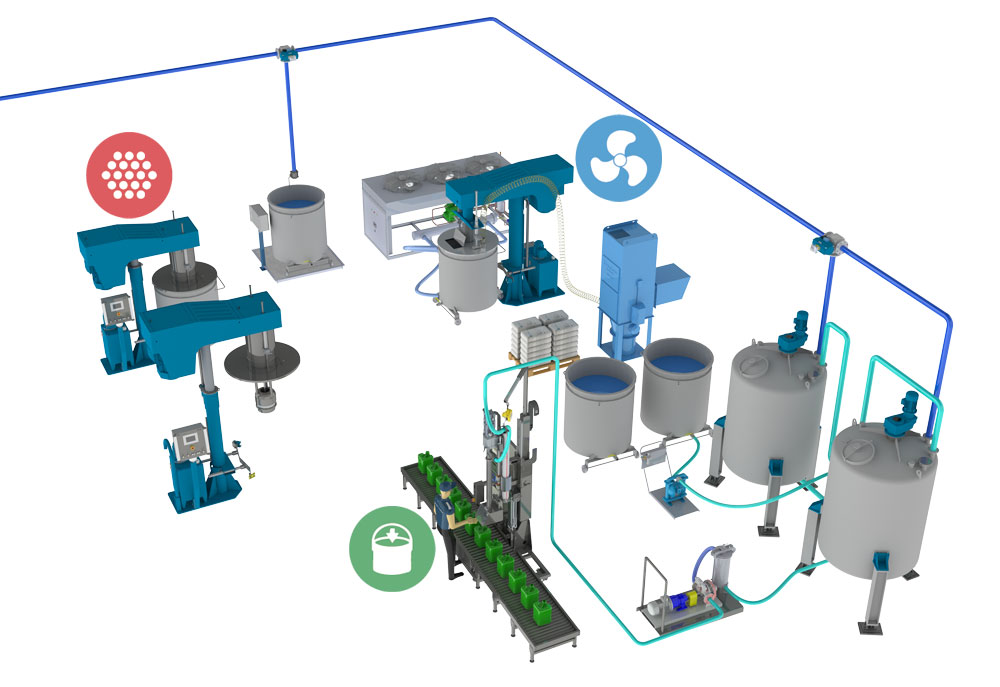

Process solutions

PHYTOSANITARY INDUSTRY

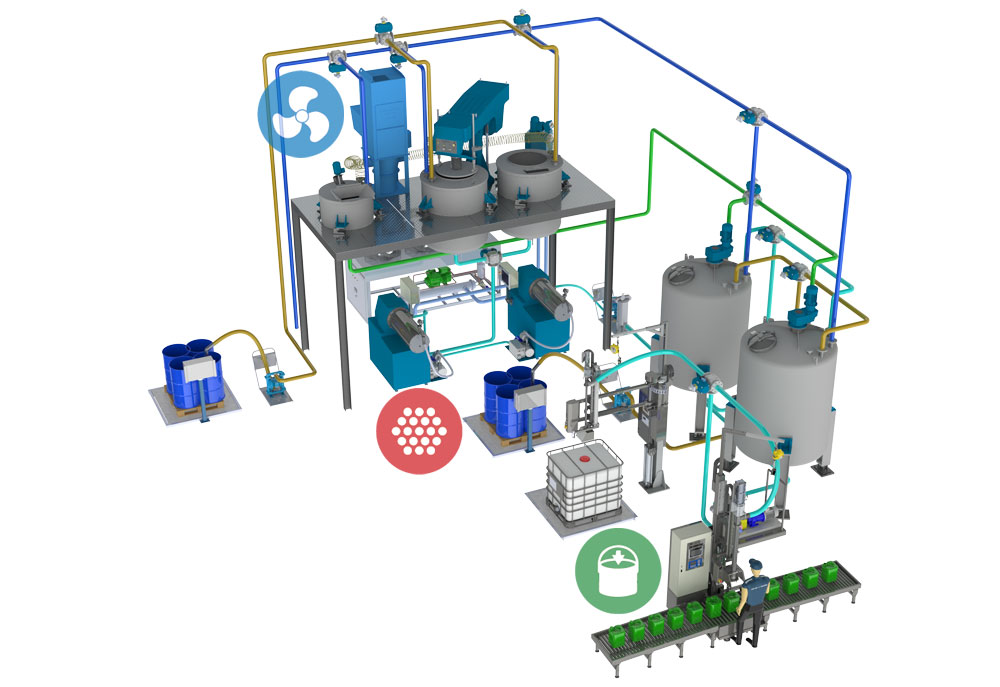

Oliver + Batlle offers efficient and innovative process solutions for the phytosanitary industry.

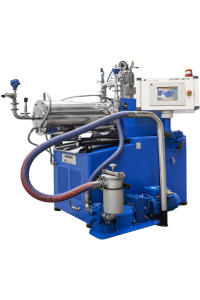

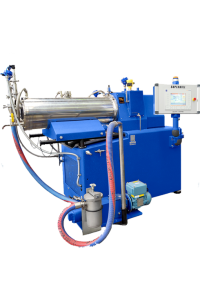

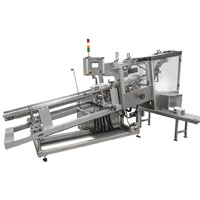

Our industrial agitators, grinding machines and filling equipment for phytosanitary products are a reflection of our company’s 60-plus years of experience. For this reason, they contribute to the optimisation of production processes by providing quality and helping to save energy and material costs.