How to Control Viscosity and Other Characteristics Specific to Paint During the Manufacturing Process

Viscosity, specific weight or colour are some of the characteristics specific to paint that must be controlled during the manufacturing process. Even if they have been previously determined during formulation, it is necessary to verify that the manufacturing process is correct and whether the desired result will be obtained once the paint is applied.

In this article we will analyse these fundamental characteristics that must be taken into account during the manufacturing process of paints.

Paint viscosity

Viscosity can be defined as the resistance of a liquid to spilling. This resistance to flowing is due to the friction between its molecules, which move at different speeds, and collide with each other making motion difficult.

Viscosity could be understood as opposite to fluidity. In this sense, the greater the fluidity, the lower the viscosity of the liquid. Its unit of measurement is the Poise, although in the International System (SI), it is measured in Pascal-second (Pa·s): 1 Poise is equivalent to 0.1 Pa·s.

With respect to the Poise, the use of its multiple, the centipoise (cP), is more common. This is mainly because the viscosity of water, the reference fluid, is 1,0020 cP at 20 °C. From the point of view of equivalence: 1 cps = 1 mPa·s.

When measuring the viscosity of paint (and that of any fluid) the measuring temperature must be included (as it has been pointed out in the case of water) as it has a great influence on the result. Normally, viscosity would be measured at 25 ºC.

There are a number of devices that can measure viscosity. In the sector of paints and related products, the most used tools are:

Orifice viscometers: Ford, Zahn and Gardner cup

Orifice viscometers such as the Ford, Zahn or BYK-Gardner cups are devices which, as their name suggests, are shaped like a cup and have an orifice that may vary in size (No. 3, No. 4, etc.) They also include a vessel for the liquid.

The measuring principle of these viscometers is based on the concept of ‘flow time’, i.e. the time it takes for a certain volume of liquid to flow through a capillary or orifice.

This time, measured in seconds, is proportional to the viscosity of the fluid. The cup number used is tabulated for a viscosity measurement.

It is a viscosity measuring tool that is very quick to use and easy to handle. They are widely used in paint, ink, and adhesive manufacturing, although not advisable for non-Newtonian fluids (whose viscosity varies with the temperature and shear stress applied to them).

Stormer Viscometer

The Stormer viscometer consists of a standardised mixer with 2 blades that are immersed in the fluid and rotated by applying weight.

Using a stopwatch, the time it takes for the blades to spin 100 times for a given weight is calculated. The viscosity is determined with the aid of an ASTM D562 table, and it is expressed in Krebs units.

Brookfield Viscometer

The Brookfield Viscometer is based on the principle of rotational viscometry. It measures the viscosity by calculating the torque required to rotate a needle immersed in the fluid being analysed at a constant speed.

The Brookfield Viscometer is based on the principle of rotational viscometry. It measures the viscosity by calculating the torque required to rotate a needle immersed in the fluid being analysed at a constant speed.

The device consists of a mixer that can rotate at different speeds, with different spindle sizes depending on the consistency of the paint. The measuring unit is centipoises (cps).

To properly measure the viscosity, it is necessary to always take the reading at the same moment after starting mixing. Remember that, since a thixotropic product is being analysed, the viscosity may vary with time.

To work with high viscosity products Oliver + Batlle offers mixing equipment: Dispermix Dual VFD, Polimix DPS y la Hidrobat planetary mixers. In the grinding equipment, the Millennium RS immersion mill, which equipped with the orbital scraper blade with a propeller can work a viscosity of up to 10,000 Poises. As for the industrial filling machines: PCH – TVH, DV Doser and the EM Putties Filling Line.

Specific weight

The specific weight of a paint is considered to be how much 1 litre of product weights in kilograms. It is also possible to measure the weight in grams per 1 cm3.

On the other hand, density should also be taken into account, since it is the amount of mass per unit volume at a given temperature.

A pycnometer or measuring cylinder can also be used to calculate the specific weight and density.

Pycnometer

The pycnometer consists of a 100 cm³ container with an overflow lid (a hole in the centre of the container through which excess product can overflow). Once filled, it is weighed to determine the density or specific weight of the paint.

By excluding the weight of the pycnometer itself, the density or specific weight can be measured accurately using a precision balance.

Measuring cylinder

To measure the specific weight or density of the paint, a graduated 100 cm³ measuring cylinder can be used. Although the procedure is very similar to that followed when using a pycnometer, the results are less accurate.

Thixotropy

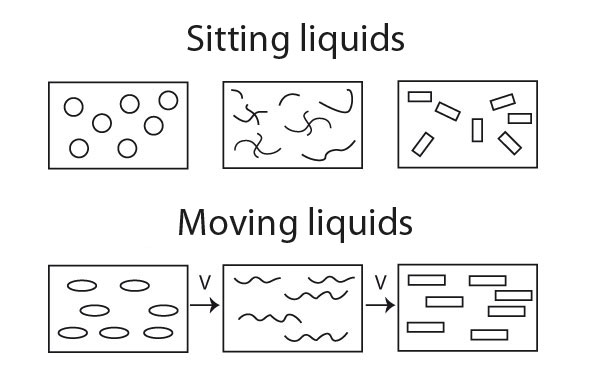

Thixotropy is the property of some liquids and gels to decrease their viscosity when subjected to shear forces. When the liquid is sitting, its particles are randomly oriented, making it highly viscous. As the speed gradient increases, the particles are oriented in the direction of the flow. This makes them slide off better and thus decreases viscosity.

This applies to paint as well as most printing inks.

Grind fineness

Grind fineness indicates the degree of dispersion of paints, i.e. the approximate largest diameter of the pigment and filler paints.

As mentioned in the article on dispersion in paint manufacturing, grind fineness influences some of the end properties of the product, such as:

- its colour,

- its gloss,

- its resistance to corrosion

- its finish appearance,

- sedimentation, flotation, and flocculation issues in case of having an inadequate value.

Grind fineness can be measured by means of a grindometer, a microscope with an image analysis system, or a laser systems. All of them were mentioned in our article about grading.

Paint colour

Colour is a visual perception or personal sensation of the composition of light reflected in a painted object. Colour depends on the stimuli that a person receives and what they can detect.

In order to define the colour of an object, such object, its illuminant, and its detector must be identified.

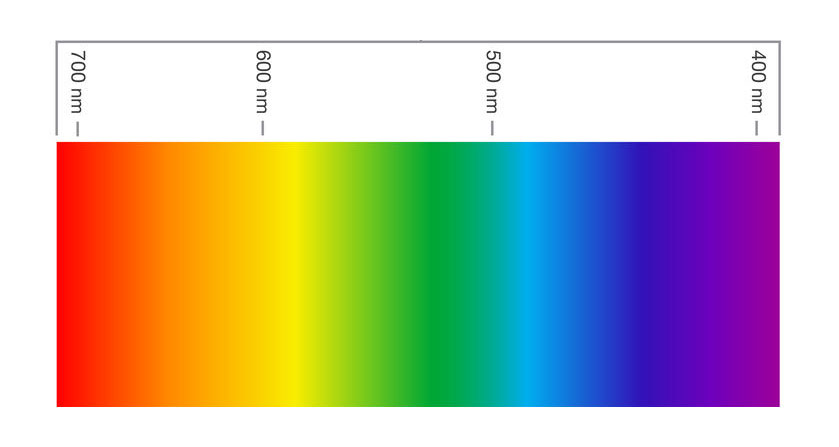

White light, which is composed of all the rainbow colours. It may be totally reflected in an object, showing a white colour, totally absorbed, showing a black colour, or partially absorbed, showing any other colour.

Some low-energy photons that make up light are absorbed by the compound that forms the pigment (producing electronic transitions or resonance phenomena in their molecules). As a result, the spectrum of re-emitted light becomes different from the one initially received.

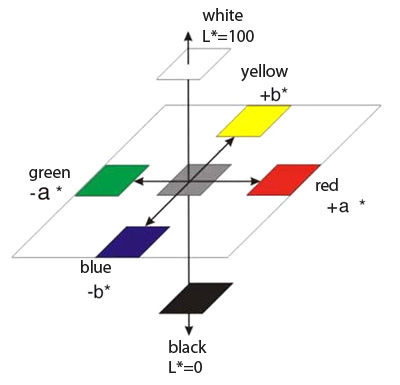

Colour measurement requires the reflectance curve that shows the amount of light reflected out of the total light impacting on different points of the visible spectrum. This amount is divided into 3 quantities or chromaticity coordinates. Nowadays, the most widely used system is the CIELab, in which L represents clarity (more or less clear or white), and a and b represent colour chromaticity: shade and saturation.

A reflectance spectrometer is used to calculate the colour curve and its coordinates. This tool is also used together with a database to determine the amount of colourant that must be added to the paint in order to match a model colour.

Colouring strength

Colouring strength refers to the colouring capacity of a pigment, a paint, or a concentrated colourant when mixed with white or any other paint colour.

Colouring strength is measured by the ‘coloured pigment / white pigment’ ratio, which is necessary to achieve an ‘established standard colour depth’.

For this purpose, the model and paint samples are spread on black and white test charts and analysed with an optical spectrometer.

Opacity or paint coverage

Coverage is the capacity of a paint to hide the colour of the surface on which it has been applied. The coverage result depends on the pigment type and percentage as well as on the thickness of the coat.

Coverage can be a result of the absorption of all visible light, as in the case of black pigments, or a result of light diffusion, which deflects light so that it does not reach the substrate and comes out of the paint coat, as in the case of white pigments.

Regarding white pigments, the level of light diffusion depends on the relationship between the pigment refractive indexes and the surrounding medium. Therefore, the greater the difference between both of them, the greater the coverage.

| Substance | Refractive index |

| Quartz, silica | 1.55 |

| Talc | 1.55 |

| Kaolin | 1.56 |

| Calcium carbonate | 1.57 |

| Baryte | 1.64 |

| Zinc oxide | 2.00 |

| Antimony oxide | 2.20 |

| Zinc sulphide | 2.34 |

| Anatase TiO2 | 2.55 |

| Rutile TiO2 | 2.70 |

| Alkyd resin | 1.53 |

| Polyacrylic resin | 1.48 |

| Polyvinyl acetate | 1.47 |

| Empty | 1.00 |

| Water | 1.33 |

To measure the coverage capacity, the same test for colouring strength measurement is performed. The product is spread on test charts (white-black), and reflectance is measured using an optical spectrometer. The relationship between the two types of reflectance obtained is called ‘contrast ratio’ and indicates an approximation to full coverage.

CR= Rb/Rw

Gloss

Gloss or specular reflection is the capacity of a paint coat to reflect the light it receives. If its capacity is high, the paint will be glossy, if it is low, the paint will be satin, and if it is zero, the paint will be matt. The smoother the surface, the glossier the paint.

Gloss is a property that depends mainly on the type of resin used to prepare the paint. It does not depend on pigment as colour and coverage do.

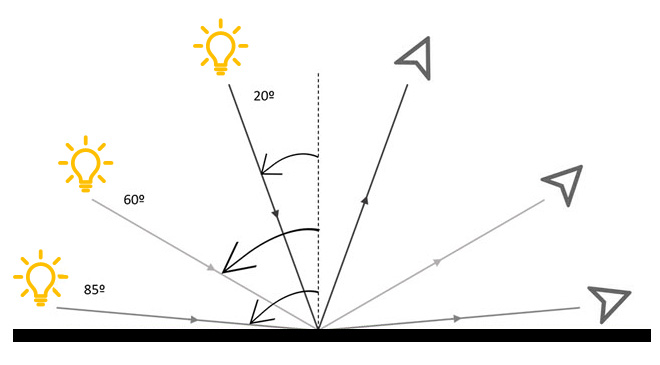

A reflectometer or glossmeter can be used to measure the amount of light reflected by a surface. For this purpose, measuring is carried out from different angles based on paint gloss:

- 20º angle: for very glossy surfaces,

- 60° angle: for surfaces with an intermediate gloss,

- 85° angle: for matt or nearly matt surfaces

The result is expressed in terms of the light percentage, specifying the measuring angle, that is received by the photoelectric sensor of the glossmeter in comparison with the light that is received from the reflection on a surface and that is considered as a model and as 100%.

In addition to the versatile characteristics of paints that have been analysed in this article, other controls may be carried out during the manufacturing process. For instance, in the case of liquid paints, stability, deposit, flocculation, flexibility, flotation, and film formation may be analysed. Regarding dry paint, thickness, hardness, adhesion, flexibility, force, abrasion, washability, among others, may be controlled.

At Oliver + Batlle, we hope you found this article interesting. We invite you to share your doubts and experience in the comments.