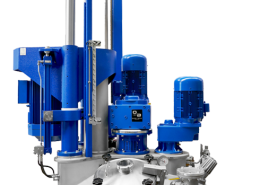

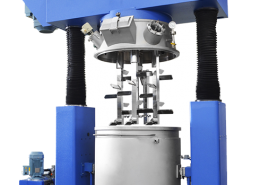

Polimix DPS

One, two or three shaft mixer – disperser for medium / high viscosity products. Cylindrical shell .

Designed for batches from 2000 liters to 15.000 liters, installed power up to 200 kW.

Designed as multi-functional units, the POLIMIX disperser have in common the mixer/disperser which can be complemented by an anchor/stirrer shaft and, depending on the nature of the application, even a third shaft with X-blade impellers.

MODELS / TECHNCAL DATA

| MODEL | WORKING VOLUME (L) | INSTALLED POWER RANGE (kW) |

|---|---|---|

| Min. / Useful | From / To | |

| DPS-2000 | 450 / 2000 | 38 / 67 |

| DPS-3000 | 650 / 3000 | 46 / 81 |

| DPS-4000 | 900 / 4000 | 54 / 109 |

| DPS-5000 | 1200 / 5000 | 66 / 124 |

| DPS-6000 | 1500 /6000 | 66 / 127 |

| DPS-8000 | 2000 / 8000 | 90 / 151 |

| DPS-10000 | 2600 / 10000 | 109 / 185 |

| DPS-12000 | 3200 / 12000 | 129 / 213 |

| DPS-15000 | 4000 / 15000 | 154 / 269 |