JOTUN is a global manufacturer of decorative, industrial, marine and protective paints and coatings.

Founded in 1926 in Norway, Jotun operates in more than 100 countries and is recognized for innovation and sustainability. Its products include:

- Pinturas decorativas

- Industrial coatings

- Marine coatings

- Protective coatings

Jotun stands out for its focus on research and development, prioritizing sustainable and environmentally friendly solutions.

PRODUCT AND OBJECTIVE

The customer requested three complete lines for high-speed packaging, with the following requirements:

- The product is water-based decorative paint, with density of 1.51 kg/dm³ and standard viscosity, designed for uniform application and optimum adhesion. Ideal for durable and resistant interior and exterior finishes. Batches from large capacity finishing tanks and packaged in 1L, 2.5L, 3.5L, 18L and 20L cans.

- Two lines to process all formats, especially the larger ones.

- One line only for 2.5L and 3.5L formats.

- Cadences (containers per minute):

- 1L (21-23 )

- 2,5L (20-22)

- 3,5L (19-21)

- 18L (16-18)

- 20L (15-17)

- Control system integrated in the customer’s MONTH.

SOLUTION O+B

To achieve the objectives and requirements set by the client, O+B implemented the following solution:

- Two packaging lines focused on large formats, consisting of the following equipment:

- PAILMANAGER container dispenser for conical (stackable) containers.

- DB-350-SQ feeding table for cylindrical containers (non-stackable).

- KETAN EUROPE labeling machine for jars and cans.

- FLASH-25 T volumetric filler for cans and jars from 1 to 20L.

- A third packaging line focused on 2.5 and 3.5 liter formats, consisting of the following equipment:

- PAILMANAGER container dispenser for conical (stackable) containers.

- FLASH-55 T volumetric filler for jars and cans from 1 to 5 L.

- KETAN EUROPE labeling machine for jars and cans.

In the first two lines, the small formats of 1L, 2.5L and 3.5L are cylindrical and not stackable, so a DB-350-SQ feeding table is included, which allows feeding at the required rates with a single operator.

The 18- and 20-liter formats are conical, allowing them to be stacked and, therefore, managed automatically by PAILMANAGER, which unstacks them and delivers them to the labeling machine and then to the packaging machine.

On line three, the 2.5L and 3.5L cans are conical and stackable, and are therefore unstacked automatically by PAILMANAGER. In this case, the labeling machine is located downstream of the filler to ensure a better labeling process.

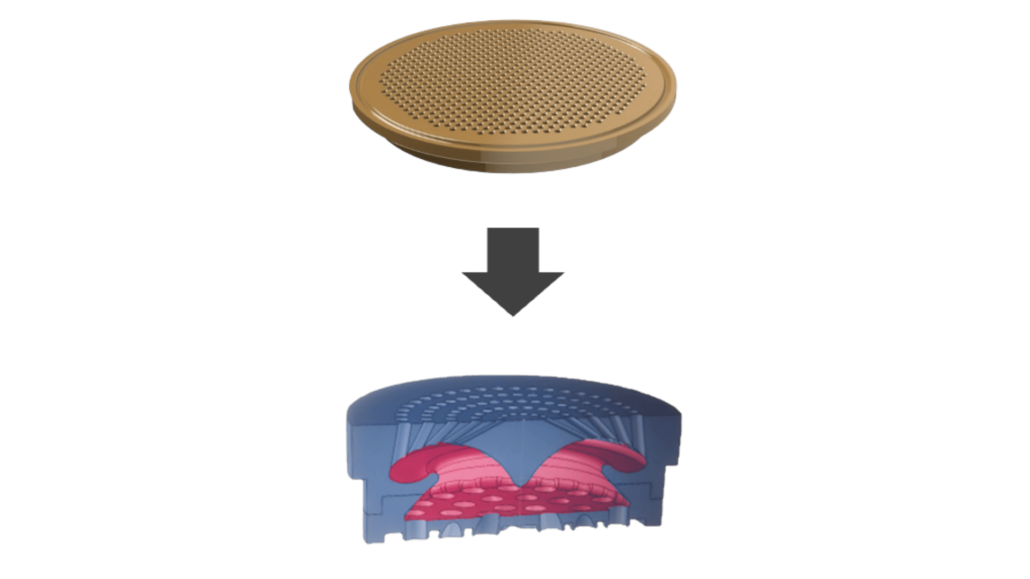

Both FLASH-25 T and FLASH-55 T packers work with a single hopper that feeds two heads, which dose 50% of the product into each pack in order to increase throughput.

All the packaging machines were equipped with a cleaning water heating system to reduce the cleaning cycle of the hopper and dosers, minimizing downtime between different production batches.

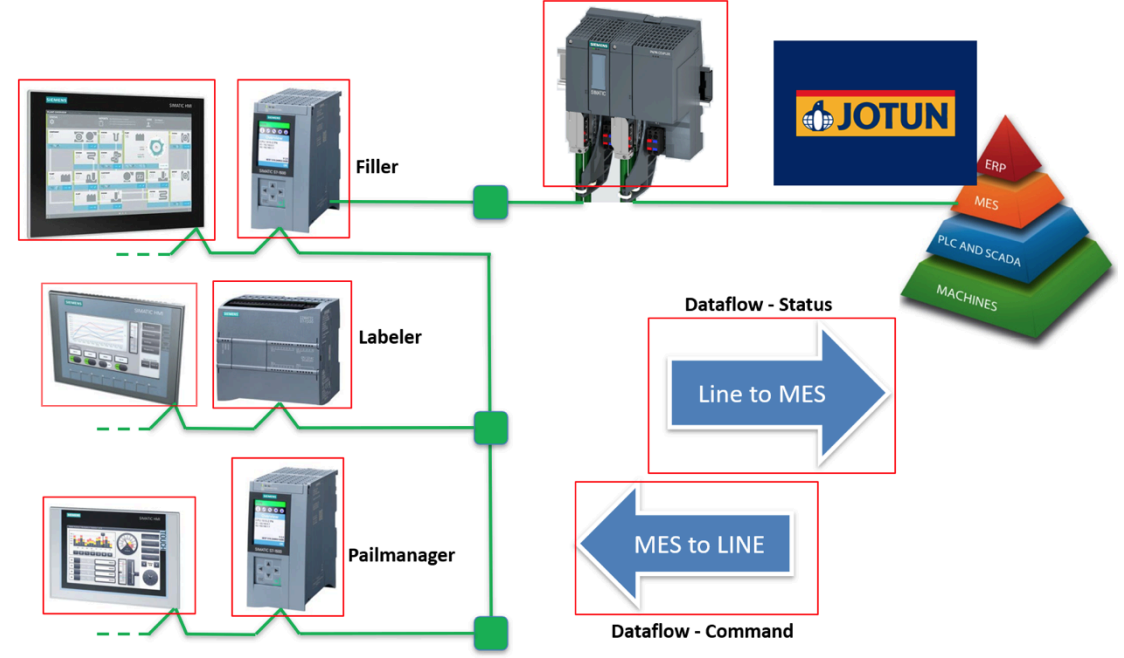

All elements of the packaging system communicate in real time with the customer’s MES.

The packaging machines are connected to the Emerson DCS system. The different systems are connected via Profinet protocol.

The packers send the following information to the system:

- Recipe number of the product / Name of the selected product.

- Machine speed.

- Count of good products.

- Count of rejected products.

- Warning and alarm messages.

- Status of the machine when running / stopped.

- Machine status ready / not ready.

Jotun MES sends to the packers:

- Order number.

- Data for label printing.

RESULTS

The project was able to fully meet the customer’s needs, achieving the required packaging rate with precision and efficiency. The implemented solution stands out for its reliability and robustness, guaranteeing consistent performance.

The systems supplied by O+B provide a sustainable operation aligned with Jotun’s quality standards.

ROI

The system was installed on new lines in a newly constructed plant, so there is no direct comparison with a previous system. However, these packaging lines are managed by a single qualified operator and perform the equivalent work of five operators in a manual process. Taking into account labor costs and considering three shifts per day, the investment is recovered in less than two years.

In addition to a rapid return on investment, automatic packaging offers a much higher level of precision and accuracy than manual packaging, optimizing operational efficiency and minimizing waste.

CUSTOMER TESTIMONIAL

“We are very satisfied with the project delivered by Oliver + Batlle. The three packaging lines installed have exceeded our expectations, achieving the desired packaging rate and significantly improving operational efficiency. The solution is highly reliable and robust, with consistent and faultless performance.”

Guruh Susanto (Project Manager – Jotun)