A bituminous mixture is made up of a binding material that encases each mineral particle of an aggregate, regardless of its grading. They traditionally come in two types: cold bituminous mixtures and hot bituminous mixtures.

Cold mixtures are those that can be manufactured with a cold or hot bituminous binder and a composition of aggregates, generally cold. These mixtures can be handled and spread at room temperature. Many of these products are storable.

Hot bituminous mixtures, on the other hand, are made with a binder that needs to be heated. The mixture temperature in this case must be above ambient temperature when applied or laid on site.

One type of binder commonly used in bituminous mixtures are hydrocarbon binders. It is a high viscosity type of binding agent, produced from natural hydrocarbons, which varies in consistency depending on the temperature (thermoplastic character) and offers good adherence to aggregates.

As for aggregates, which come from fragmented rock, their chemical and surface activity against water and bituminous binders depends on their composition and grading.

Bituminous mixture properties

In general, bituminous mixtures must be manufactured according to the properties required for the application they are to be used for, which can be extremely diverse. There are a series of properties that can be strengthened to a greater or lesser extent, taking into account the mixture’s composition, the materials, the dosing and the product’s manufacturing conditions.

These properties include:

- Stability: the ability to support loads and resist the stresses to which it will be subjected, while retaining a certain series of deformation values.

- Resistance to plastic deformation: bituminous mixtures feature a viscoelastic behaviour, leading to a series of deformations when low speed and high temperature loads are applied to it. The material’s required rheology for the specific project in which it is to be applied, a concept that was introduced in our article on thixotropy, must be taken into account at the manufacturing stage.

- Fatigue resistance: bituminous mixtures are elastic at low temperature and at high speeds, but load repetition produces progressive wear due to material fatigue which results in an increase in deformation and cracking.

- Slip resistance: when this type of product is manufactured to be applied on pavement or road wearing courses, for example, it must provide adequate slip resistance for a given number of years.

- Impermeability: as in the case of slippage, bituminous mixtures used on top layers must protect the infrastructure against water infiltration action. Sometimes, impermeability can also be ensured with the lower layers, for example when using a porous mixture that removes surface water by infiltration.

- Durability: sun, air, water or ice as well as vehicle oils or fuels affect the durability of the mixture used, for example on the wearing courses.

These properties will be strengthened or modified, depending on whether the product is to be applied on wearing courses, intermediate layers or base courses, since the function and exposure of their mixtures to environmental conditions is different.

Bituminous mixture manufacturing process

Hot bituminous mixtures are manufactured with asphalt bitumens at a higher or lower temperature, depending on the viscosity of the binder used. The aggregates that go into the mix are also heated so that they do not lower the binder’s temperature when they are added to the mix.

Bituminous binders provide efficient and flexible bonds, for example in road construction, thanks to their viscoelastic properties, as mentioned above. Since binder behaviour varies depending on ambient temperature, the mix should be manufactured using the binder that best adapts to the temperature range to which the mix is to be subjected once it has been applied to the pavement.

There is also a number of products that modify asphaltic bitumens and are obtained by dispersing polymers or rubber, among other materials, in the mix. These modified products can improve the binder’s properties when exposed to high or low temperatures.

Manufacturing equipment

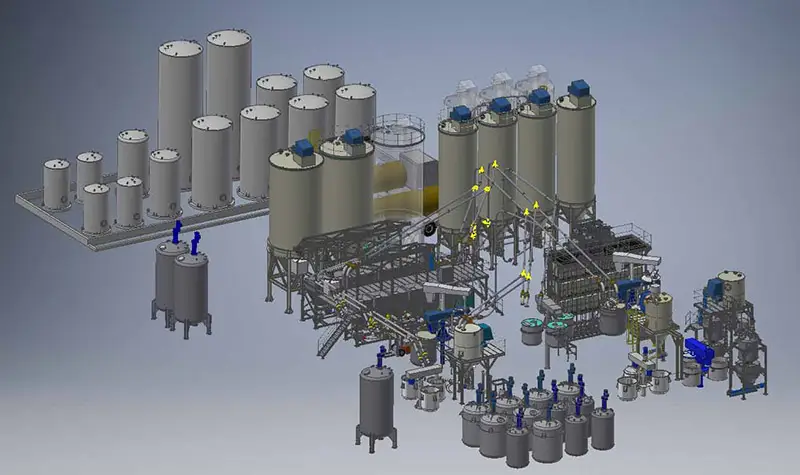

Just as the bituminous mixture formula is adapted to the application’s requirements and the place where it will be used, Oliver + Batlle’s bituminous mixtures’ manufacturing machinery is adapted to each product’s characteristics.

The industrial agitators for bituminous products by O+B offer technified vessels combining fast axes and slow anchors as well as monitored heat supply. Our technification, together with our engineering team, develops turnkey projects that are adapted to a specific product’s manufacturing process.

We offer solutions for asphaltic bitumen manufacturing for large industrial batches as well as for small and medium-sized production. For mixtures with any type of fluidity, our solutions such as the Hidrobat Planetary Mixer, or DISPERMIX mixers, offer a robust solution that requires only a simple maintenance for a greater optimisation of the production process.

We manufacture storage tanks for this type of product with heated systems (that can reach up to 180º), full insulation capacity and an internal stirrer that keeps the binder continuously moving. In addition, we design the necessary process engineering to integrate any of our equipment into your manufacturing plant.

Request further information about our manufacturing equipment for bituminous products and follow us on LinkedIn to keep up to date with our news.