Before commissioning a new manufacturing plant, a series of factors must be considered to optimise processes and leverage the available space for efficient production.

Apart from knowing the specific characteristics of the product manufacturing process, in order to design a manufacturing centre, it is essential to look for solutions in terms of safety, health and environmental protection that comply with regulations and legislation in force in the building place and that enable optimal performance of employees at the plant and of external collaborators.

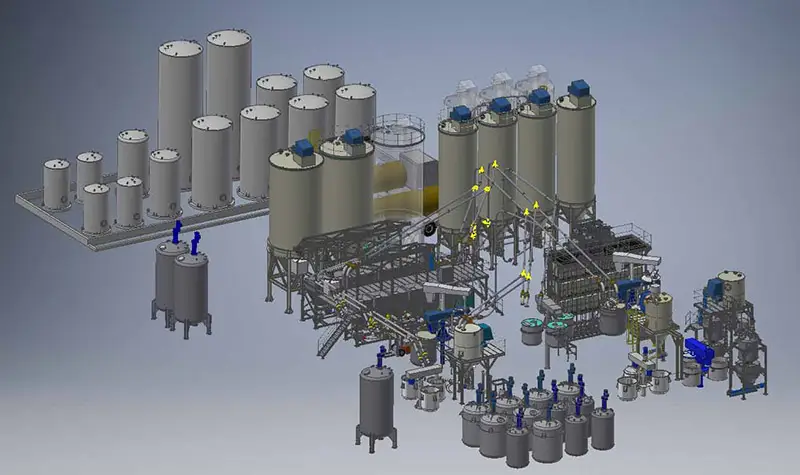

With more than 60 years of experience in the industrial sector, Oliver + Batlle offers a comprehensive service for turnkey construction of complete manufacturing plants or for the incorporation of facilities into existing plants adapted to your needs.

Manufacturing plant design and planning

Once production goals have been set by the client and specific needs and characteristics have been analysed, the first step in designing the manufacturing plant consists of carrying out the basic engineering project.

In this stage, production processes are established by means of a “process diagram” or P&ID (piping and instrumentation diagram/drawing). Thanks to this diagram, O+B technicians can clearly and simply identify the production process flow as well as the necessary equipment and tools. Piping, valves, pumps, controls, alarms…, the diagram shows each component of the manufacturing process by means of an identifying symbol.

In addition to the process diagram, the basic engineering project includes other specifications such as required electrical power, water or compressed air (if required), equipment and platforms dimensions, piping installation size and dimensions…

Implementation and commissioning

Each manufacturing plant turnkey project developed by Oliver + Batlle is led by a Project Manager in charge of detailed engineering according to the characteristics approved in the basic engineering project.

In the detailed engineering stage, the design proposal is verified to confirm it or modify it in case any design assumption must be changed. This review is particularly suitable for projects in which a large period of time has elapsed between basic engineering design and project completion. There may also be economic or legal reasons requiring the modification of the initial project.

Once the basic engineering project has been verified or modified, the definition and calculation stage of each part that makes up the manufacturing process components begins. In this way, by providing as many details as possible, no building element is left undetermined in the final project.

In addition to the list of necessary equipment and its corresponding detailed specifications, the detailed engineering project includes an implementation plan for the plant, control systems and the levels of industrial automation specified by the client. Pumping assemblies, measuring stations, weighing hoppers, production software…, all the necessary elements to achieve the set productivity goals are perfectly determined.

Once the project and its dimensions have been calculated considering the whole project and each component, the result must be compared with applicable regulations and laws in each case. Every special regulation that must be considered for building the plant shall be expressly mentioned in the project. In this way, it is possible to obtain all the necessary documentation before starting the work.

One of the advantages of carrying out a turnkey project with Oliver + Batlle is that the technical team involved in both basic engineering and detailed engineering is part of our company, which, in turn, manufactures and supplies industrial equipment to be implemented. In this way, the design and planning of the manufacturing plant are adapted from the outset to the components that will be subsequently supplied for building the plant.

Building the industrial manufacturing plant

In turnkey projects, O+B provides each client with a complete layout of the facility and all the necessary services for adequate implementation. In this way, we ensure that all the building work carried out on the manufacturing plant by the client is a true reflection of the project.

In addition to production process facilities, when building the plant it is necessary to take into account the distribution of other elements such as the infrastructures for the treatment of different types of waste, personnel and vehicle accesses, storage, loading and unloading areas… in short, all the necessary spaces to carry out direct or indirect activities related to production.

Sustainability, respect for the environment, safety and digitalisation are 4 basic keys to consider when executing any manufacturing centre. For this reason, O+B offers, for example, automated solutions for solid material vacuum incorporation that can be implemented on production process (for greater equipment safety), piping cleaning and emptying equipment (to reduce waste and waste treatment costs), liquid and solid management systems, and so on.

Request further information about our turnkey projects for building industrial manufacturing plants and follow us on LinkedIn to stay tuned with our news.