Dispersion, the First Step in Paint Manufacturing

Dispersion is a key phase in paint manufacturing. When it comes to emulsified paints, for example, it is widely considered as the most important phase.

The goal in the dispersion phase is to cause most of the agglomerated pigments and fillers that are part of the formula to be stably separated as individual particles.

Depending on the properties desired for the paint being manufactured (colour, coverage, gloss, etc.), the amount of particles separated by the dispersion process shall vary. Market, use, and application of the paint will also be taken into account.

One of the most important features to consider in the dispersion process is the need to combine and stabilise materials that, in many cases, are incompatible: pigments, additives of different chemical nature, water, etc.

Special mechanical equipment is used to achieve the desired goal in an efficient way, such as:

- High-speed blade agitators which provide the dispersion needed for manufacturing plastic paints. A great example of which are the O+B Dispermix

- Microelement mills that achieve higher dispersion degrees. Some examples are the Supermill, Mill-ennium or Optimill equipment.

When the dispersion process has not been carried out correctly, the finished product may show a series of issues after a certain storage time has elapsed. These issues include phase separation, sedimentation, loss of gloss, greater viscosity or heterogeneous colour, which indicate issues in the dispersion phase of the manufacturing of such paint.

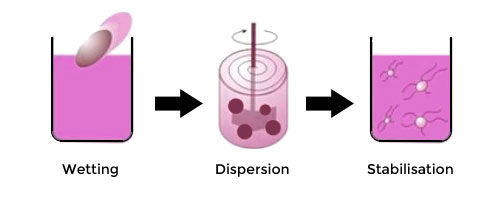

Our article on grading explains the different phases that make up the dispersion process: wetting, deagglomeration or actual dispersion, and stabilisation. The correct execution of these phases, adapted to the characteristics of the product, will contribute to the achievement of the aforementioned goal.

What factors affect dispersion?

The wetting and compaction undergone by the pigments and fillers make up the aggregates and conglomerates which are correctly separated into discrete particles during the dispersion process. To this end, as mentioned above, air and water are replaced by the liquid elements that make up the formula: resins, solvents, and additives, among others.

This process is very difficult, because displacing air and wetting the solid components involves a physical property known as surface tension.

Surface tension and wetting

All liquid elements are subject to molecular attraction forces known as surface tension. This force is responsible for the volume of a liquid taking on a spherical shape. Surface tension varies according to the pertaining liquid and its unit of measurement is dyne/cm.

For the wetting process to be carried out correctly, the attraction force between the solid and liquid molecules needs to be greater than the attraction force of the liquid molecules.

This is why the wetting additives are crucial to help decrease the surface tension of the liquid, enabling the wetting of fillers and pigments. Thus, the ‘separating’ mixture for the discrete particles can be correctly introduced.

Factors related to product formula that affect dispersion

As you may already know, the basic components in the formulation of a paint are: pigments, fillers, resins, solvents and additives.

Each of these elements is related to several factors that affect the dispersion process:

Factors to be taken into account about pigments and fillers:

To achieve an optimal dispersion process, first, the pigments that are the most difficult to wet should be added and dispersed, so that they are subjected to the wetting action of liquid elements for the longest time possible, and under the most favourable conditions.

It should be noted that inorganic pigments are more easily and quickly wetted than organic pigments that have a much smaller particle size.

Since fillers are an inorganic element and have larger particle sizes than pigments, they are the most easily wetted solid elements, so they must be added after pigments.

Finally, it should be noted that the storage conditions of the solid elements of the formula strongly affect the ease of dispersion of its particles.

Resins

Some resins are more wetting than others, so, if different resins are involved in the formulation of the paint, the most wetting resin will be chosen to form the initial paste.

The minimum amount of resin to be used is determined by the pigment’s oil absorption. Thus, it will be necessary to use a sufficient amount to ensure that the dispersed particles are completely covered. Oil absorption varies greatly depending on the type of pigment. Its absorption value determines the maximum % of pigment to be used in the pastes.

The following table shows the most common pigment concentration percentage according to the type of pigment used:

| Pigment | Concentration (%) |

| Titanium dioxide | 60 |

| Carbon black | 8 |

| Black iron oxides | 50 |

| Yellow iron oxides | 35 |

| Cr and Mo yellow and orange | 50 |

| Organic yellow | 15 |

| Toluidine red | 25 |

| Red iron oxides | 60 |

| Phthalocyanine blue and green | 10 |

| Prussian Blue | 20 |

| Ultramarine blue | 60 |

| Chrome green | 40 |

Factors related to solvents and additives

All solvents promote wetting, so it is important to add some when starting to mix. If several solvents are used in the formula, those that are less volatile or have a higher proportion in the formula are to be chosen in order to compensate for the one that evaporates by heating.

As for additives, the ones to be included are those that boost dispersion, such as wetting and dispersing agents.

Factors related to the mechanical equipment chosen for dispersion: Dispermix

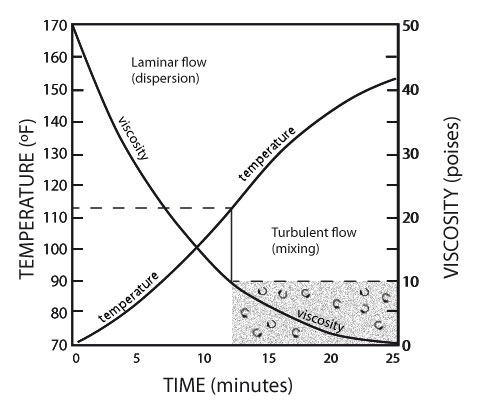

Viscosity, temperature and dispersion time also affect the dispersion process. Let’s see how using Dispermix optimises these factors:

Viscosity

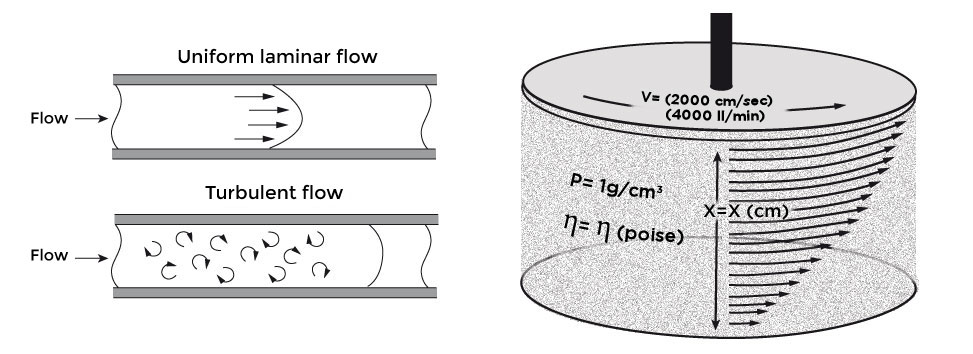

For a good dispersion effect with our equipment Dispermix, the viscosity achieved should enable working with laminar flow. This should be between 20 and 100 Poises.

Optimum viscosity value depends on two opposing premises: on the one hand, low viscosity promotes the wetting process and, on the other hand, high viscosity promotes shearing strength. In addition, maximum viscosity is also limited by the power of Dispermix.

Temperature

Temperature

The optimum temperature that the paste must reach to effectively use Dispermix is 50 to 60ºC working with a laminar flow.

From here, the paste’s motion goes from the laminar flow, where it looks like a ‘doughnut’ that turns around the shaft, to a turbulent flow with chaotic motion and incorporation of air.

Time of dispersion

Time of dispersion is usually extended for about 20-30 minutes once all the solid elements of the formula have been added. After this period, viscosity decreases due to the effect of temperature, as well as shear strength.

The following chart shows how the relationship between temperature, viscosity and time works:

Once the correct wetting and dispersion of the particles is achieved with Dispermix, the stabilising elements must be added to immediately achieve an acceptable stabilisation of the dispersion achieved or a paste viscosity suitable for treatment in a mill, or for completion.

Oliver + Batlle equipment for dispersion

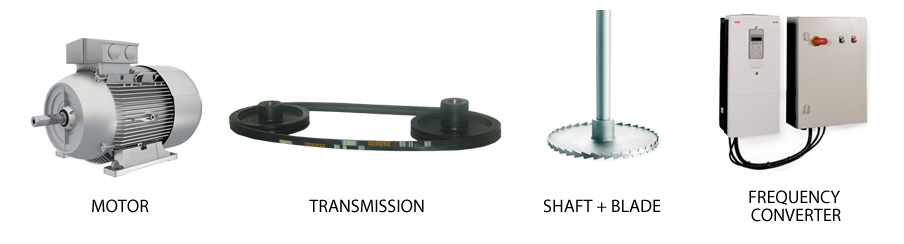

All the equipment designed for the dispersion process in the manufacturing of paints and other related products have a series of elements in common: the motor, the transmission from the motor to the shaft (belts or pulleys), the blade shaft, and the frequency converter.

The sawtooth blades in the shaft are crucial in the dispersion process.

The rotation speed of the blade creates an area of turbulence at the edge of the teeth with intense product laminar flow. This causes high friction that generates shearing and force, which prevents the formation of agglomerates and, if any, their breakage, while the solid elements are being added.

The area of the greatest turbulence is about 60 to 70 mm away from the blade teeth. This is where 75% of the kinetic energy required for the dispersion process of the solid elements takes place.

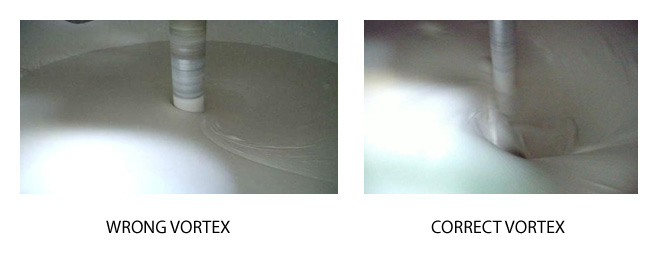

Right in the joint of the blade to the shaft, the motion produces a vortex in the product, which is the main area where the dispersion of the solid elements takes place.

Besides the blade type to be used, a good dispersion requires:

- A vessel diameter that is 2-3 times longer than the diameter of the dispersion impeller.

- A recommended distance from the dispersion impeller to the bottom of the vessel that is not greater than the radius of the impeller.

- Peripheral (tangential) speed of the dispersion impeller calculated according to the formula: . The optimum peripheral (tangential) speed to achieve good dispersion must be between 24 and 28 m/s

- A recommended viscosity of the liquid to be dispersed ranging from 30 to 60 Poises.

There are different types of sawtooth blade. The most recommended blades for the dispersion process are the Cowles, Double Suction and Cowles-Sevin.

Cowles Blades

Cowles Blades

This is the most common disperser blade. The teeth’s design produces a great shearing effect on the product. It is suitable for both the mixing process and the dispersion process.

Although it is manufactured in AISI 304 stainless steel as standard, its protection against wear is improved when manganese steel wear liners are added to its teeth.

Double Suction Blade

It’s a composite double blade. The bottom has a traditional sawtooth blade and the top has a radial-axial blade.

The double suction blade has the standard dispersion capacity of the sawtooth combined with the high axial effect of product flow, which results in increased product circulation (VORTEX) through the sawtooth, thus reducing the dispersion time. We must take into account though, that there is an increase in electricity consumption and product temperature.

Cowles-Sevin Blade

It is a traditional sawtooth blade with cup-shaped openings, which increase the axial flow of the product.

These cups, which are open alternately above and below the blade plate, increase both axial flow and dispersion capacity.

As for the elements in which the dispersers are applied, they can be fixed or portable vessels.

Oliver + Batlle‘s dispersing and mixing equipment features the outstanding range Dispermix.

Ground-fixed low and medium viscosity dispersion equipment for portable vessels are Dispermix VF, and its lab version Dispermix VF-L. Equipment installed through a platform for fixed vessels are: Dispermix VF-E, Dispermix Dual VFD, Polimix Coaxial DPS / OR, and for high viscosity, the planetary mixers Hydrobat MPVDV.

At Oliver + Batlle, we hope you found this information interesting. We invite you to request more information about our dispersion equipment through our contact section.

Share any doubt or experience in the comments section and follow us on LinkedIn to keep up with our news.