INTRODUCTION

At Oliver + Batlle, we offer a wide range of specialized machinery for the production of water-based phytosanitary products, a format that is increasingly in demand in the industry due to its advantages in handling, safety, and efficacy.

Among the pesticide products processed under this system, we find:

- Herbicides and algaecides: for weed control.

- Insecticides and acaricides: for combating insect pests.

- Nematicides: aimed at eliminating soil-borne diseases in crops.

- Fungicides: such as the common copper oxychloride, for controlling fungi.

- Fertilizers and growth products: to promote crop development.

In the past, these products were supplied in powder form, which posed significant risks of contamination, dirt in handling areas, and inhalation toxicity. The evolution towards liquid formulations has eliminated these drawbacks, enabling the production of concentrated suspensions or flows, which are much safer and more efficient.

Advantages of liquid pesticide products:

- Cleaner and easier handling compared to powder products.

- Easier and more accurate application dosing.

- More efficient storage in drums.

- Greater biological activity compared to powders.

- Better distribution of active particles in the liquid medium.

- More uniform particle size.

- Allows for simpler and more efficient cleaning of application equipment.

Liquid bases used in formulations:

- Water

-

- Solvents (currently being phased out for environmental and safety reasons)

- Water and solvent mixtures: where each phase is prepared individually before mixing.

- Oil

To carry out the production of these products, Oliver + Batlle offers equipment for all stages of the process:

- Dispersion

- Grinding

- Finishing

- Filtration

- Filling

Below, we detail each of these stages and the machinery available in our program to ensure maximum efficiency and quality in the production of water-based phytosanitary products.

DISPERSION

The dispersion phase is essential in the production of water-based phytosanitary products as it ensures the homogeneous incorporation of the active ingredient along with the additives and liquid components of the formula.

Common components in dispersion:

- Active ingredient (or technical grade), generally in powder form.

- Liquid medium: water, solvent, oil, or combinations of these.

- Glycol or paraffin oil: between 2% and 8%.

- Dispersant: in proportions of 2% to 10%.

- Wetting agent: between 0.5% and 3%.

- Antifoam agent: around 0.1% to 0.5%.

- Thickener: added between 0.2% and 0.4%, previously prepared in a 2% aqueous solution to ensure proper dilution and avoid the formation of lumps or gels.

In some formulations, high-purity silica may be added as a rheological modifier.

The active ingredient must be incorporated into the liquid medium using a mixer-disperser, which ensures its proper dispersion and prevents the formation of clumps.

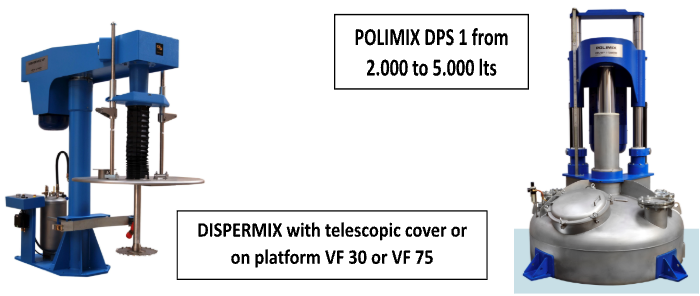

Recommended equipment: To perform dispersion, equipment from the DISPERMIX range is primarily used, sized with the required power according to the batch volume:

- From portable models to platform versions for higher-capacity productions.

Over time, due to the need to improve working conditions, avoid operator exposure to harmful dust, and protect the environment, the use of closed systems such as POLIMIX has been incorporated. These systems, with specific installations for raw material feeding, guarantee a safer and cleaner working environment.

POLIMIX can be:

- Single-shaft dispersers.

- Coaxial models equipped with wall scrapers, ideal for high-viscosity products and complex formulations.

Recommended turbines and working conditions:

- Sawtooth turbines or HDM (High Dispersion Mixing) type.

- Optimal peripheral speeds: between 24 and 28 m/s.

- The diameter of the tank should be 2 to 3 times the diameter of the turbine to ensure proper fluid dynamics.

Formulation parameters:

- Powder solids concentration: Generally between 30% and 70% by weight.

- Common viscosity of the mixture: Usaully between 800 and 1,200 cPs. With these characteristics, the standard power of each machine model assigned according to batch size is sufficient without the need for over-sizing or using higher-power equipment.

Design and materials of equipment: Dispersion tanks should be made of AISI 316 L stainless steel and feature cooling jackets.

Temperature recommendations:

- Temperature of the coolant: below 4 ºC.

- Maximum process temperature: should not exceed 30 ºC to protect heat-sensitive active ingredients.

Foam control: In this type of formulation, foam formation during dispersion is common. If this issue is detected and working with a POLIMIX system, it is recommended to use the vacuum loading system, which minimizes foam generation and improves process efficiency. This aspect should be adjusted according to each product and validated during initial testing.

GRINDING

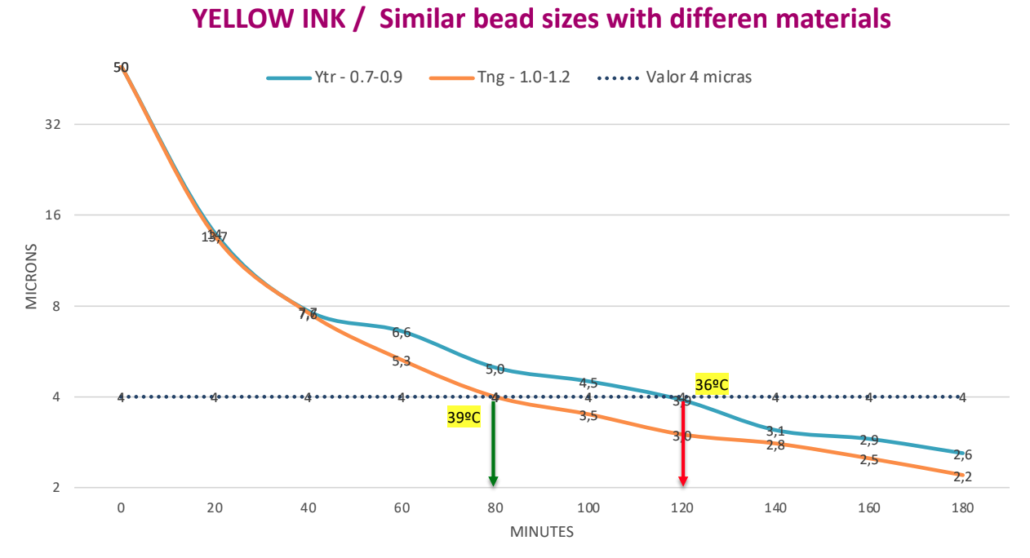

In the grinding phase, the separation of active ingredient particles that were not fully disaggregated during dispersion takes place. Additionally, some active ingredients may undergo a particle fracture process, resulting in smaller particle sizes. This stage is crucial to ensure that phytosanitary products meet regulatory standards and technical specifications, such as CIPAC regulations for pesticide products.

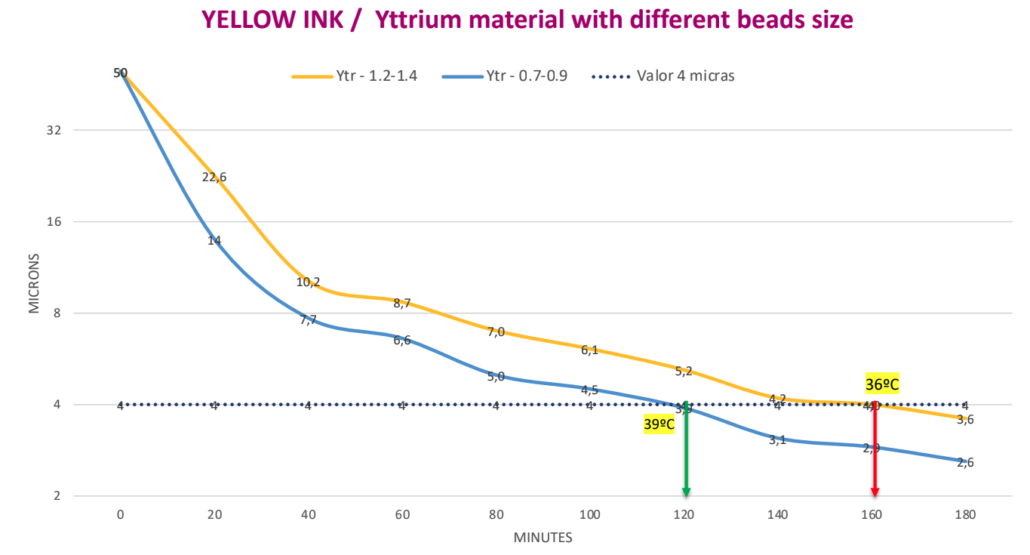

One of the key objectives in this process is to ensure that 50% of the particles are smaller than 5 microns, and 90% are smaller than 10 microns, guaranteeing the quality and effectiveness of the products.

Available types of mills:

- Continuous mills: SUPERMILL.

- Batch mills: MILL-ENNIUM.

Both types of mills are effective for particle disaggregation. While the Supermill generates shear forces within its milling chamber, the Mill-enium combines shear forces and impact, providing better energy transmission and a significant advantage in terms of production capacity.

Comparison of results in tests: In tests carried out with copper oxychloride, both machines showed comparable quality results, but with differences in energy consumption and manufacturing time. The data was as follows:

- Mill-enium RS-20 (copper oxychloride): 0,06 kW/lt.

- Supermill EHP-50 (two passes of copper oxychloride): 0,259 kW/lt.

This implies an energy savings of 77% when using the Mill-enium compared to the Supermill. Additionally, in terms of manufacturing time, the Mill-enium RS-20 would process 1,100 liters in 67 minutes, while the Supermill EHP-50 would need 330 minutes, resulting in an 80% time saving.

Granulometry characteristics of products:

- For initial particle sizes between 150 and 200 microns, two passes are required to achieve sizes smaller than 5 microns.

- For initial particle sizes between 40 and 50 microns, one pass is sufficient to reach sizes smaller than 5 microns.

Summary of operating parameters for both machines:

Supermill EHP:

- Materials in contact with the product: Duplex stainless steel.

- Feeding pump: Gear or helical stainless steel AISI 316L, with adjustable speed.

- Grinding shaft: Belt transmission, electric motor with adjustable speed.

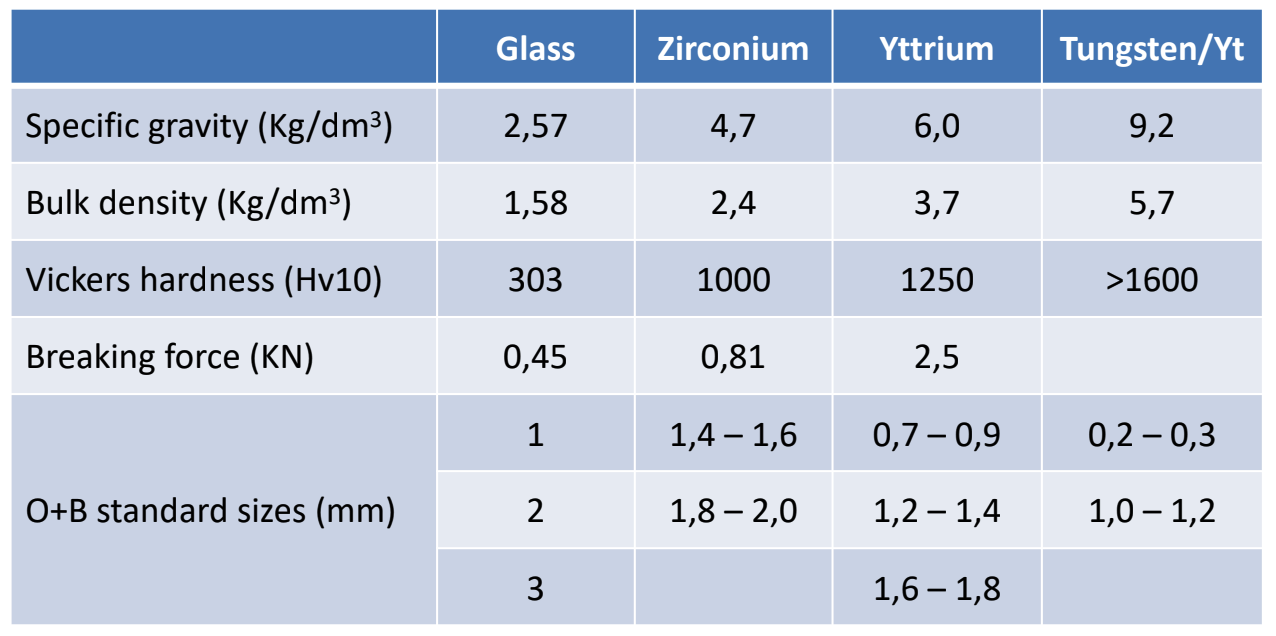

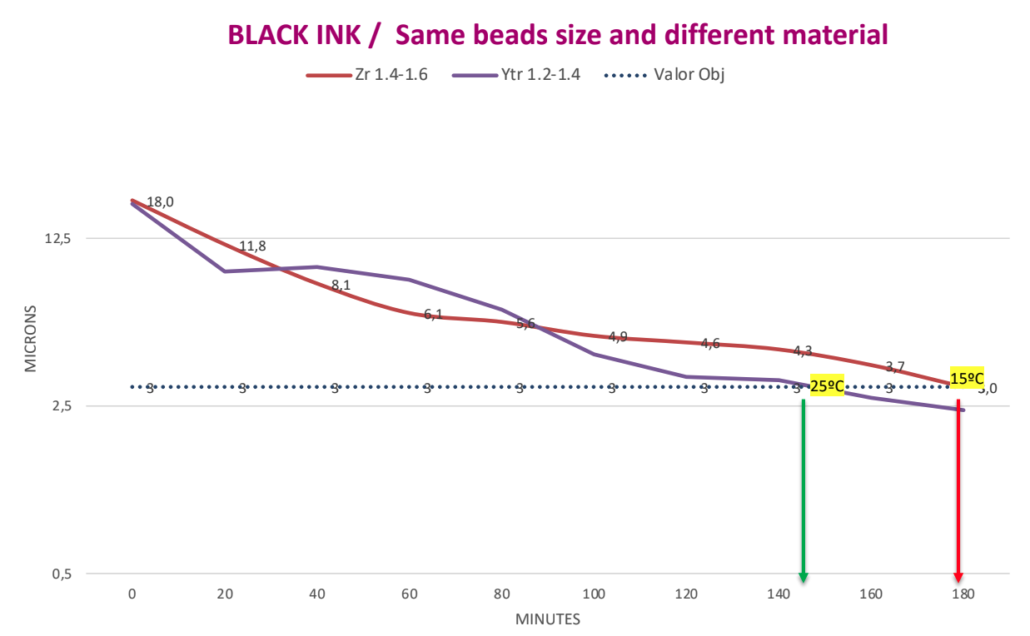

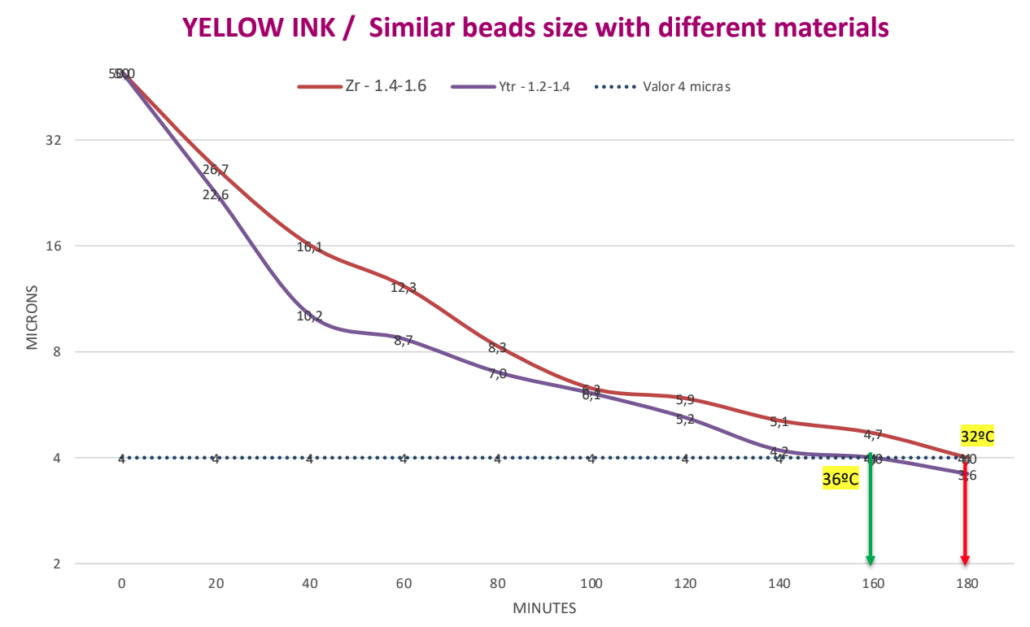

- Grinding balls: Zirconium 1.8-2.0 mm in the first pass, and 1.2-1.4 mm in the second.

- Grinding chamber: Provided with cooling jacket, with water supply at 4°C.

Mill-enium RS:

- Materials in contact with the product: Stainless steel AISI 316L or Duplex.

- Grinding shaft: Tungsten carbide peg and counterpeg system, turbo-type turbine.

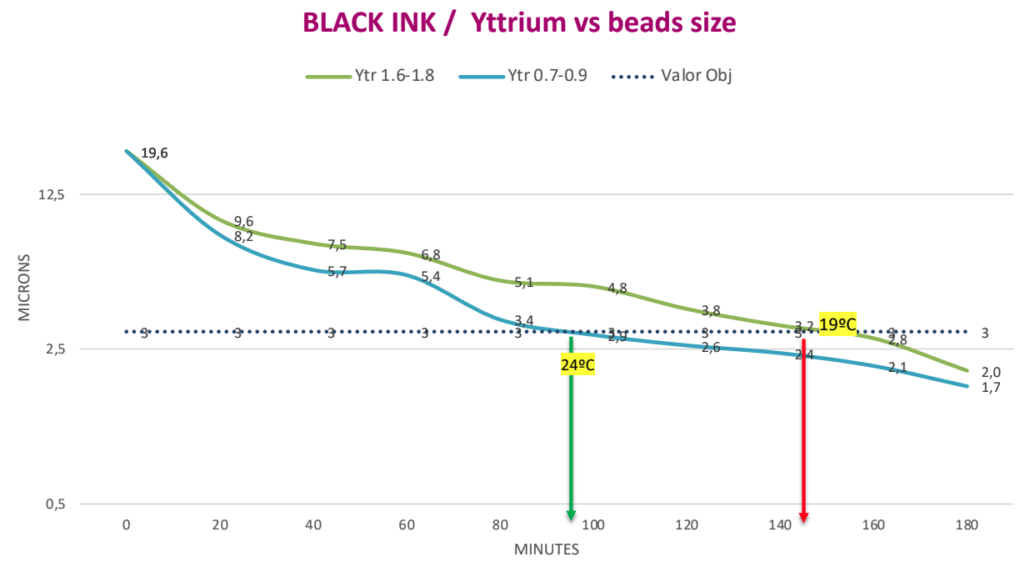

- Grinding elements: Yttrium (0.7-0.9).

- Grinding basket: Cooling recirculation system, process vessels with cooling jacket, water at 4°C.

Pumping and filtration: Between milling and finishing, product pumping through a pumping and filtration group is required. This process should be done with a pneumatic pump and a bag filter. The objective is to remove coarse raw material particles and milling balls, so it is recommended to use a monofilament nylon bag with 50-micron filtration.

FINISHING OR STORAGE OF PRODUCT

Once the product has passed through the milling phase, it will be stored in a tank, with the tank capacity determined by the plant’s production volume. It is essential that this tank is equipped with an efficient agitation system to ensure the homogenization of multiple production batches and, if necessary, the addition of additives such as thickeners to adjust the formula.

The most suitable type of agitation for this process is a mixer equipped with radial axial turbines, with an off-center shaft in the tank. For tanks with capacities exceeding 5,000 liters, it is recommended to install a second radial axial pumping turbine without dispersion hammers, which facilitates the incorporation of prefabricated thickeners.

Additionally, these tanks should be designed with variable speed, allowing the adjustment of the agitation speed according to the rheological characteristics of the product, ensuring its homogeneity. As in other stages of the process, the parts in contact with the product should be made from AISI 316L stainless steel to avoid contamination.

PUMPING AND FILTRATION

Before proceeding to filling, the product must be pumped using an appropriate pumping system that includes a filter to ensure that the final product delivered to the customer is free of impurities from the manufacturing process.

A recommended universal base equipment is the GBE Electric Pumping Group, which includes a pump made of AISI 316 stainless steel and an AGF 51 or AGF 53 bag filter with 5-micron filtration. Since many phytosanitary products tend to generate foam during the filling process, the pumping system must include a speed selector. This way, a slow filling speed can be set at the beginning of the process, and once the filling nozzle is submerged, the filling speed can be increased.

FILLING SYSTEMS

The most common containers in the agrochemical industry are 5 and 10-liter polyethylene drums. To fill these containers, a gravimetric filling system with a submersible headstock, such as the OB-DRUM model, can be used . It features a scale up to 25 kg, and a filling nozzle of the appropriate diameter for the type of drum to be filled.

If production increases and the number of containers to be filled is considerable, the PALET-1500 model, fitted with a rotary headstock can be used. This system allows packaging groups of drums placed on pallets, optimizing production capacity and workflow.

Tests Performed in O+B Laboratory with Phytosanitary Products:

- Active Ingredient: Copper Oxychloride

- Pyrimethanil

- 80% Sulfur

- 93% Sorbitol

- 24% Oxifluorfen

CONCLUSION

In summary, the production of phytosanitary products in aqueous suspension offers numerous benefits over powder formats, especially in terms of safety, efficacy, and ease of handling. Oliver + Batlle offers an integrated solution throughout the entire production process, from the dispersion of active ingredients to the final product packaging. Thanks to its range of specialized machinery, manufacturers can ensure more efficient production with optimal quality control in a safe environment for both operators and the environment.

Oliver + Batlle’s commitment to innovation and advanced technology ensures that production plants can maximize their capacity, reduce energy consumption, and improve the quality of the final product. Additionally, laboratory tests support the effectiveness of their solutions for processing complex active ingredients, such as copper oxychloride, pyrimethanil, and other common compounds in the phytosanitary industry.

In an increasingly competitive and demanding sector, choosing the right machinery is essential to optimize resources and comply with regulations. Oliver + Batlle positions itself as a key ally in the manufacturing of phytosanitary products in aqueous suspension, offering solutions that meet the highest standards of quality, safety, and sustainability.