What is thixotropy and how does it influence the manufacturing of paint and related products?

Thixotropy is a property of some products which change their viscosity and become more fluid when subject to constant shear force, e.g., in the mixing stage. The longer the fluid is under shear stress, the less its viscosity.

In normal conditions, a thixotropic fluid is highly viscous (equilibrium viscosity) but becomes liquid or more fluid when subject to shear force. This type of product takes certain time to reach its equilibrium viscosity when an instantaneous change in shear rate occurs. For example, when a mixer’s shear work is stopped or slowed down, the fluid tends to reach equilibrium viscosity, which is always higher than its viscosity when it is being mixed.

To better understand the concept of thixotropy, definitions can come in handy, such as that of the Chambers Dictionary of Science and Technology (1971): ‘Rheological property of fluids characterised by a high viscosity at low stress, but a decreasing viscosity as stress increases’. Another good definition is that of H. A. Barnes, J. F. Hutton and K. Walters in their book ‘An Introduction to Rheology’ (1989), which defines thixotropy as the ‘time-dependent decrease of viscosity […] under low stress or a constant speed gradient, followed by a gradual recovery when the stress or gradient is removed’.

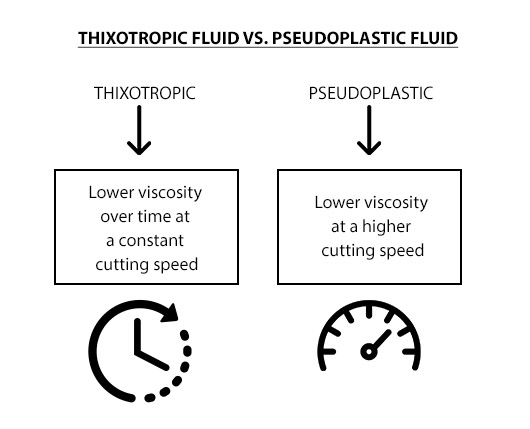

Thixotropy is sometimes wrongly used to define the behaviour of pseudoplastic fluids, which do not show a viscosity-time correlation. It is important to understand the difference between a thixotropic fluid and a pseudoplastic fluid. A thixotropic fluid decreases in viscosity over time at a constant cutting speed, while a pseudoplastic fluid’s viscosity decreases with increasing cutting speed.

Fluids that exhibit the property opposite to thixotropy, i.e., those to which mixing over time causes caking, are called rheopectics or, sometimes, anti-thixotropic. These products are much less common.

Thixotropy and the manufacturing process

Oliver + Batlle‘s mixing equipment is prepared to manufacture products with different thixotropy levels.

Products such as varnishes, lacquers, synthetic paints and traditional water-based paints are not thixotropic products. In other words, they maintain their fluidity characteristics over time after manufacturing.

On the other hand, wall or floor waterproofing paints, wood sealants, putties for wall or bodywork repair, and some silicones are some of the products that are usually very thixotropic.

It is important to know the level of thixotropy when choosing the right machinery for manufacturing thixotropic products, given that the mixing equipment must have the necessary power to break it while maintaining a constant speed over time. Once manufactured, the product’s temperature drops and its viscosity increases when mixing stops, acquiring the appropriate state for its application.

Equipment such as the Dispermix Dual, for medium and high viscosity products showing a certain level of thixotropy, and the Hidrobat planetary mixer, suitable for highly thixotropic products with high viscosity (and also for pseudoplastics), offer high efficiency when it comes to manufacturing these products.

In their finishing stage, thixotropic products must be stored in tanks fitted with mixing equipment, also known as finishing tanks. Oliver + Batlle can provide any finishing tank with the type of turbine that best suits the specific characteristics of the product to be manufactured.

Filling thixotropic products

Thixotropy must also be taken into account when choosing the equipment necessary for the filling stage. The main problem when it comes to filling this type of fluids is the difficulty of extracting them from their containing vessel.

Portable vessels with a maximum capacity of 1,500 litres are used in the manufacturing of a thixotropic product with mixers such as Dispermix Dual or planetary mixers such as Hidrobat. Hydraulic press systems are used to empty these vessels, such as the PH, or PCH – TVH Hydraulic Press, that can extract products with medium or high viscosity thanks to its pressing pressure.

Volumetric measuring and dosing systems, such as the DVB 250 are used once the product has left the manufacturing vessel. In addition, these dosing units can be combined with container feeding systems, conveyor tables, lid applicators or container closing systems for further process automation.

Oliver + Batlle has filling equipment such as the EM 52 model designed for filling high viscosity and thixotropic products in containers with a volume of up to 250 cc. This type of equipment is frequently used for filling offset inks, putties used in body repairs or construction putties.

For filling thixotropic products in containers larger than 250 cc, the DG 60 or the OB 130 gravimetric filling machines are also available. These industrial filling machines are supplied with pumping assemblies suitable for high viscosity thixotropic products, fitted with electric positive displacement screw pumps. Thixotropic products must be mixed at the time of filling so as to avoid suction issues with the pumps.

Oliver + Batlle invites you to contact our specialists and ask for further information about our equipment for manufacturing products featuring thixotropy as a property.

Share any doubts or experiences in the comments section and follow us on LinkedIn to keep up with our news.