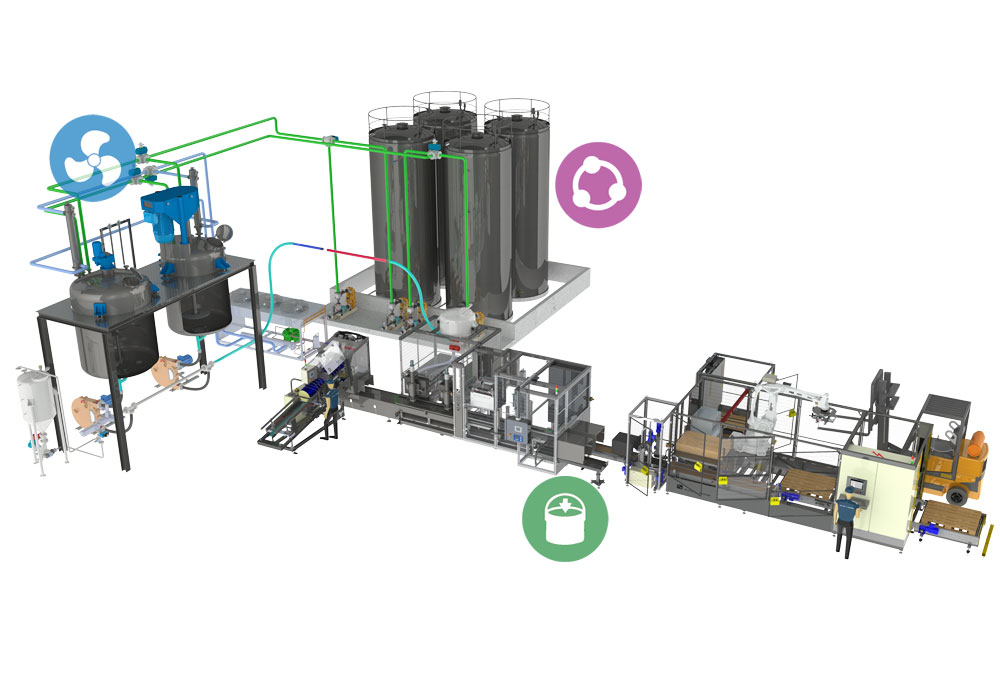

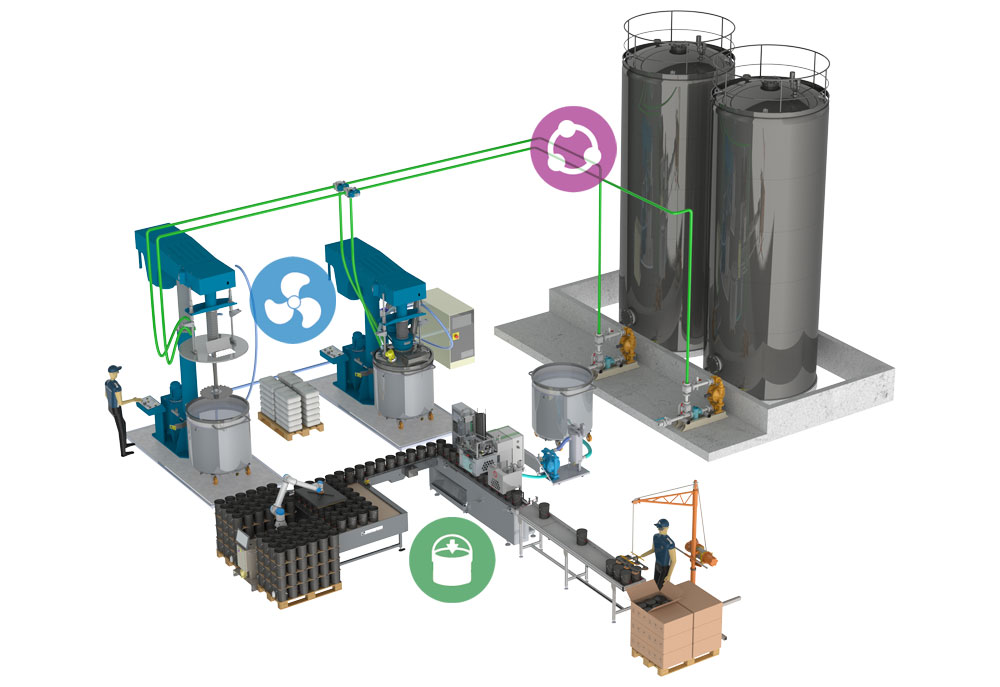

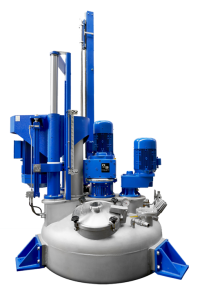

At Oliver + Batlle, we manufacture technological solutions for the mixing of transparent varnishes that include elements such as steam condensers, cooling systems, our own metalworking solutions, and a wide range of mixing mechanisms for different processes.

Our dispersion solutions for pigmented varnishes, intended for small batch production, guarantee a fast, safe and reliable production process thanks to specific optional equipment.

Optional equipment includes:

- Blades from Cowles, HDM, Radial-Axial, Spangenberg, Sevin, etc.

- Steam condenser.

- Telescopic lids.

For the production of pigmented varnishes in large batches, we offer you one of the most highly acclaimed dispersion equipment on the market: Polimix DPS-ORC, which also includes the possibility of adding automated solid loading systems such as Dispervac.

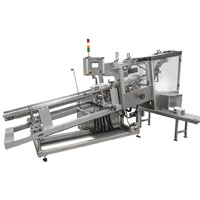

Oliver + Batlle designs customised transfer systems that adapt to the needs of each plant and type of production. We supply finishing tanks for simple miscibility cooling processes by means of cooling jacket or half jacket.

Ask us about our turnkey solutions and the wide variety of designs that make the most of the nature of the base liquids for greater production optimisation.