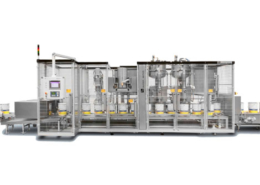

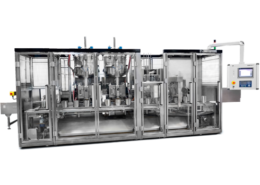

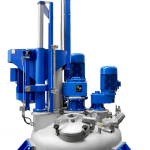

FLASH-52

Automatic line characterized by its versatility in performance for all kinds of cans, from 50 to 250 mm diameter, with double pitch transport system 130-260 mm to reach higher output.

For dosing products of low and medium viscosity from 0.1 up to 5 litres per stroke.

HMI control panel with PLC included in IP-54 versión and IP-54/ATEX “hybrid” (zone 1 and 2 in accordance with the distance form the dosing zone, and HMI in non-classified area). Thus, allowing management of all stations of the filling unit, as well as the display of status, warnings and emergencies.

Machine of very easy maintenance thanks to the incorporation of the automate, and suppression of pneumatic logic system.

Advantages

- HMI control panel with PLC

- Touchscreen to manage control of all the stations of the filling unit.

- Display of : Status, warnings and alarms, allowing fast diagnostic of failures.

- Possibility of remote technical service.

Accessories

- Closing devices, press-on lids or “crown” type

- 1 ½ Valve with pneumatic actuator

- Product level control

- Hopper with automatic cleaning system

- Lid detector

- Leak detector

- Anti-skinning agent proportioner

- Empy cans feeding table (different configurations available)

- Closing station for lug-lids

- Full container accumulation table

- ATEX Certificate for EEx versions

Aplicaciones

- Paints

- Varnishes

- Glues

- Adhesives

- Liquid Inks

- Others

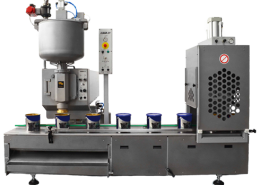

MODELS / TECHNICAL DATA

| MODEL | OPERATION | FILLING VOLUME | OUTPUT (container /min.) |

|---|---|---|---|

| Liters | 1 Liter / 5 Liters | ||

| FLASH – 52 | Electro-Pneumatic | 0,1 – 5 | 24-27 / 15-17 |