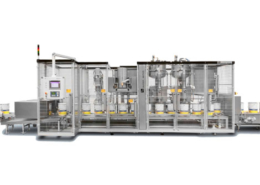

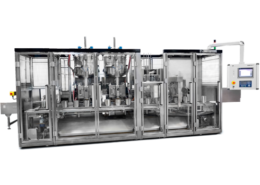

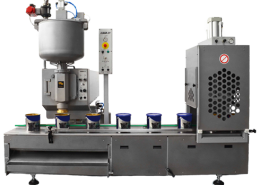

FLASH-25 – Volumetric Filling Machine

High output, fully automatic filling line, from 1 L to 20 L. PLC controlled, and high performance equipment directed towards significant productivity improvement, automatic format change, recipe storage and fast cleaning.

Flash-25-S model is equipped with 1 dosing head whilst the “T” model incorporates two identical dosing head.

Advantages

- Format changeover < 1 min. Quicker and straightforward production cycles management.

- Easy maintenance (maintenance tasks can be performed in each station of the filling line).

- Diagnosis for troubleshooting.

- Remote assistance (incidents can be detected online and assessed, as well as software modification or upgrades).

- Recipe management.

- Data gathering system.

- Increase of the operability of the lines.

- Decrease of the learning curve.

- Display of data and statistics to optimise performance of the filling line.

Accessories

- Lid wrong closed detector (laser)

- Anti-skinning agent proportioner DA-250-E

- Automatic pail denester.

- Closing device station.

- Others: Consult us.

Applications

- Paints

- Varnishes

- Glues

- Adhesives

- Liquid Inks

- Others

MODELS / TECHNICAL DATA

| MODEL | OPERATION | FILLING VOLUME | OUTPUT (container /min.) | Nº OF HEADSTOCK |

|---|---|---|---|---|

| Liters (per stroke) | 5 Liter / 20 Liters | |||

| FLASH – 25-S | Electronic | 1 – 20 | 18-20 / 11-13 | 1 |

| FLASH – 25 – T | Electronic | 1 – 20 | 19-21 / 15-17 | 2 |