This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

What is thixotropy and how does it influence the manufacturing of paint and related products?

Thixotropy is a property of some products which change their…

22/04/2021/by marketingDT360

21/07/2020/by marketingDT360

What are plastisols and how are they made?

Plastisols are compounds made with PVC resin, a plasticiser replacing…

29/06/2021/by marketingDT360

Types of waste in the paint and related products industry

Growing environmental awareness together with existing regulations…

31/01/2021/by marketingDT360

28/05/2020/by Equipo Oliver+Batlle

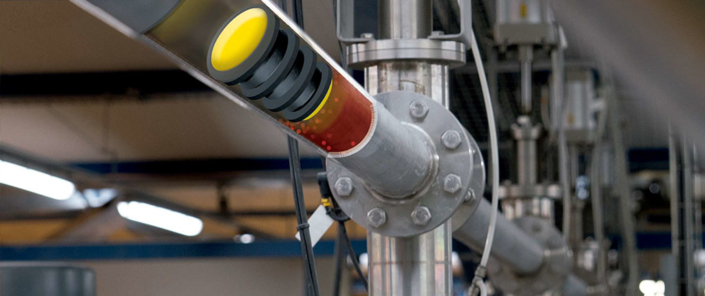

Pipeline cleaning system for paint factories

Having an automated pipeline cleaning system in paint and paint-related…

15/01/2021/by marketingDT360

Paint filling process. What kind of filling machine should I choose?

The paint filling process is a crucial phase in the manufacturing…

22/12/2020/by marketingDT360

New Flash 52: introducing the latest version of the O+B filling machine with new features and advantages

Oliver + Batlle introduces the latest version of the Flash 52…

28/05/2020/by Equipo Oliver+Batlle

Finishing Tanks TA

Installed with support legs or on platform.

Batches from 1.000 to 20.000 L.

Batches from 1.000 to 20.000 L.

Dispermix VF-L

Laboratory / Pilot disperser

Batches from 0,1 to 150L.

Batches from 0,1 to 150L.

Dispermix Dual VFD

Disperser + loop blade. Batch from 400 to 1.500 L. Portable vessels.

The manufacture of liquid phytosanitary products by means of dispersers and mills

The manufacture of liquid phytosanitary products has some characteristics…

16/07/2021/by marketingDT360