How to optimise the wet grinding process for paint production?

The wet grinding process occurs when a product is transformed from solid to liquid, regardless of its viscosity: paints, inks, enamels, nail varnish, among others. In this process, agglomerates that were not separated in the dispersion phase (due to the electro-physical bonding of some components) are broken by applying extra energy.

This wet grinding process uses beads or micro beads, which are accelerated inside a chamber thanks to the movement of the blades and pegs located within the chamber. The resulting turbulent and chaotic movement produces a high shearing and force power, which breaks the bonds between particles, thus reducing the size of the agglomerates and bringing the particles (pigments and fillers) to their initial size. This process achieves a perfect and homogeneous distribution of the particles in the base liquid.

O+B’s wet grinding equipment makes it possible to optimise the dispersion and grinding process according to product characteristics and the specific production type taking place in the factory. Thus, high-quality fineness, transparency, gloss and pigment development is achieved in any ink, paint, pigment, varnish and adhesives manufacturing process, among others.

What factors affect the wet grinding process?

The smallest possible agglomerate size is key in achieving a more efficient wet grinding process. Hence, the importance of a good pre-dispersion process to achieve maximum separation of these agglomerates.

In addition, other factors to take into account to achieve a better wet grinding process are:

During pre-dispersion

- The disperser shaft’s speed (between 24 and 28 metres per second).

- The diameter ratio between the vessel and the blades.

- The fineness or size of the agglomerates obtained in the pre-dispersion phase, before the grinding process

- The presence of additives that help during pre-dispersion.

During the grinding phase

- The size of the micro beads.

- The viscosity of the final paste resulting from the dispersion phase (recommended between 25 and 45 Poises).

- The maximum temperature of the paste at the end of the grinding process, since temperature increases during the wet grinding process.

Wet grinding equipment (mills) are versatile machinery that regulates the motion and force so that it can be adapted to product characteristics and production goals.

Oliver Batlle’s grinding equipment is offered in 3 different types: immersion grinding equipment (described in a previous article), continuous grinding equipment and recirculation grinding machinery. The latter represents an evolution from continuous mills, as it features a circulation system that changes the direction of paint flow so that the product can go through the grinding chamber more times. The recirculation system prevents pressure and temperature issues, ensuring that the micro beads break the agglomerates several times.

Since immersion mills, also referred to as ‘batch mills’, have already been discussed, we will now analyse continuous mills, such as O+B’s Supermill EHP and recirculation mills, such as the Supermill Plus SMP.

Continuous and Recirculation mills

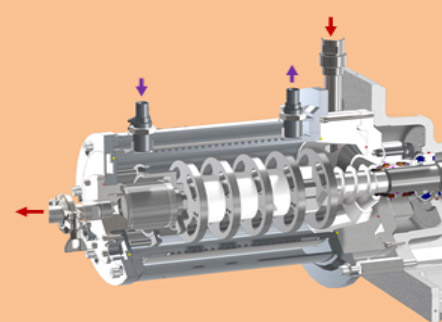

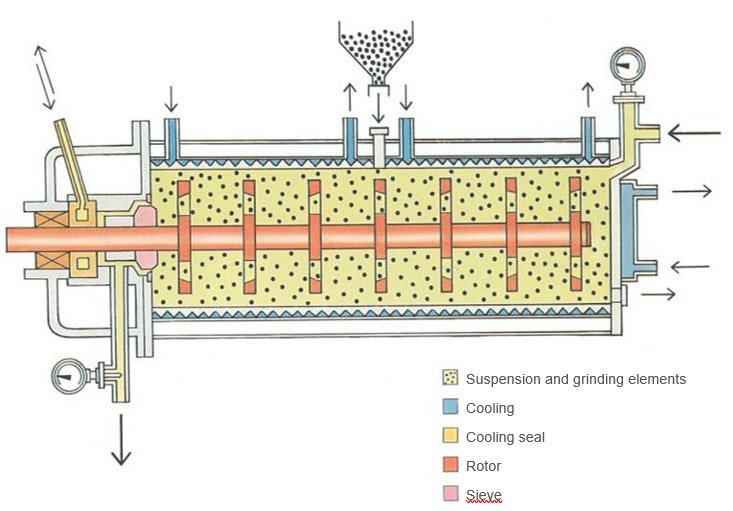

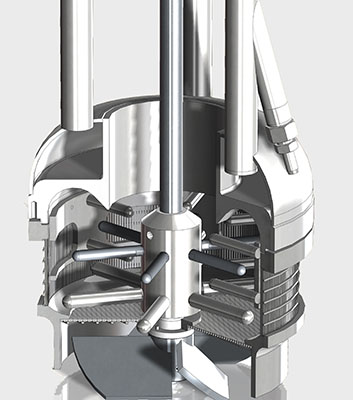

When the wet grinding process is carried out with continuous equipment, the grinding paste is forced through a closed chamber by a pump. This chamber contains the micro beads, the shaft with the blades that move the beads, and a sieve that keeps the beads or micro beads inside the chamber, letting the grinding paste out of the chamber once it has gone through the mill chamber.

The grinding chamber is also equipped with a cooling jacket, in order to control excessive heating of the product.

In summary, the basic components of continuous mills are:

- cooled grinding chamber, which can be horizontal or vertical;

- shaft with propellants: blades and pegs;

- sieve;

- motor and transmission: frequency converter;

- mechanical seal.

Let us take a closer look at the different components of this type of wet grinding equipment.

Sieve

The sieve is the component that prevents the micro beads from exiting the grinding chamber and the grinding paste to pass through. The span of the sieve, i.e. its opening or micron size, depends on the size of the beads used in the process. This should be 2.5 to 3 times smaller than the size of the micro beads.

There are 2 types of sieves:

-

- Radial screen : composed of an adjustable spacing of 0.4, 0.6 and 0.8 mm. It is highly resistant to wear and the output surface is relatively small.

- Johnson sieve: it is a sieve that always has the same spacing. It offers a large outlet surface, and much higher flow rate than adjustable sieves. It suffers greater wear than the flap grinding disc.

- Radial screen : composed of an adjustable spacing of 0.4, 0.6 and 0.8 mm. It is highly resistant to wear and the output surface is relatively small.

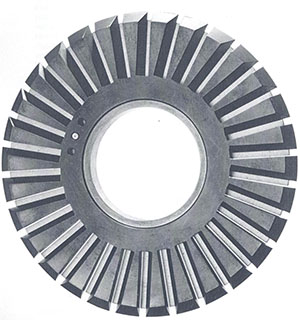

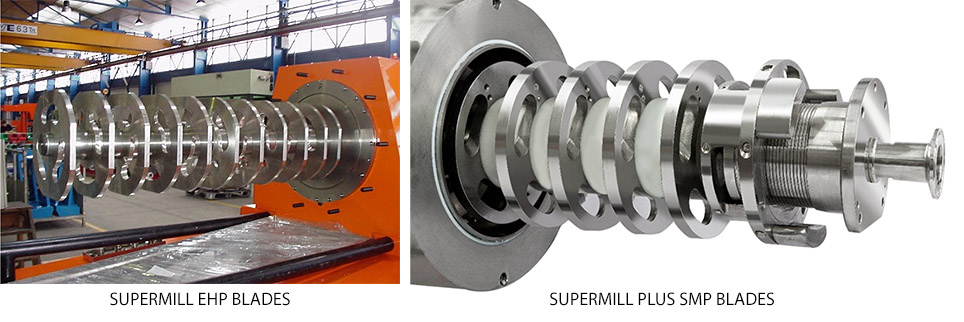

Blades and pegs

Both O+B’s Supermill Plus SMP and Supermill EHP wet grinding machines are equipped with blades of the same material, but different in shape. The Supermill EHP, a continuous grinding machine, has a blade with two flat faces, while the front face of the Supermill Plus SMP’s blade, a recirculating grinding machine, is fitted with a metal block designed to increase the turbulence of the beads.

Pegs and counterpegs are used to generate turbulences in immersion mills such as the Mill-ennium RS.

Mechanical seals

Continuous grinding equipment are watertight machines. To close the vat without stopping the shaft, a mechanical seal needs to be installed. This seal can be comprised of several parts or it can be a single part or cartridge that is directly installed.

The quality of the mechanical seal and its correct installation determine to a great extent the quality of the mill. A possible breakage would result in a coolant leakage into the vat where the product is located, causing contamination of the product.

Micro beads or beads

Another component of continuous and recirculating mills are the beads or micro beads that intervene in the wet grinding process. These grinding beads are the ones that impact and rub with the agglomerates of the paste optimising the process.

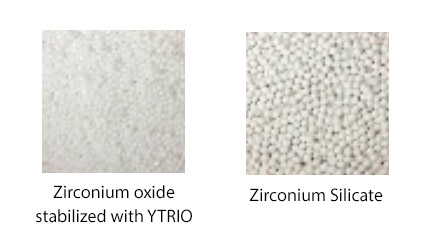

The greater the difference between the densities of the micro beads and the grinding paste, the greater the force energy. The most commonly used micro beads, in decreasing order of quality, are the following:

| Specific density | Apparent density | Ø mm Available | Application in O+B equipment | |

| Yttria-stabilised Zirconia oxide | 6.0 kg / l | 3.6 kg / l | 0.7-0.9 / 1.2-1.4 / 1.6-1.8 | Supermill Plus SMP

Supermill EHP |

| Zirconia Silicate | 3.8 kg / l | 2.3 kg / l | 1.4-1.6 / 1.8-2.0 | Supermill Plus SMP

Supermill EHP |

To achieve optimal wet grinding process, the size of the beads must be proportional to the size of the agglomerates. In this way, the beads will not go into the potential spaces between the large agglomerates, since they would lose the ability to impact against them. If the agglomerates were too small and the beads too large, the opposite effect would occur (the agglomerates could get into the spaces between the beads).

In this type of continuous and recirculating mills, the recommended micro bead loading in the grinding chamber is of 70 to 85% of its useful volume.

If the particle size resulting from the pre-dispersion is adjusted and homogenised as much as possible, determining the most suitable bead size for the process in question will be much more accurate.

What criteria should be taken into account to choose the type of mill that will best suit a manufacturing plant?

In order to determine the type and model of the mill that is best suited to a paint and related products factory, one must bear in mind that the result of the grinding process does not only depend on the grinder chosen, but also on the pigments and fillers used.

When using improved pigments and fillers, it may be the case that only the dispersion process achieves the desired result.

Oliver + Batlle provides our clients with a team of technicians and consultants who recommend the option that best suits each project when choosing a grinding and dispersion equipment.

Some aspects to be considered beforehand could be:

- Continuous mills have no volume limitation to process.

- The more energy the mill can apply to the product, the better the results.

- Automation: different levels of automation of the grinding process can be established depending on the needs of each industry.

Oliver + Batlle invites you to contact our specialists and ask for further information about our wet grinding equipment.

Share any doubts or experiences in the comments section and follow us on LinkedIn to keep up with our news.