Inks can be classified into 2 different groups according to their components and properties. On the one hand, there are liquid inks and pigment concentrates, which are commonly used to colour plastics, and on the other, offset inks, also known as greasy inks, which are used for printing on different substrates and through different processes.

Liquid inks are low to medium-viscosity products that usually dry by evaporation of the solvents they contain. In the graphic arts field, they are usually applied in flexography and rotogravure. Greasy inks, on the other hand, have a high viscosity and tend to dry by oxidation (the oils of which they are composed oxidise on contact with oxygen in the air). They are used, for example, for newspaper or magazine printing, for printing on plastic or metal substrates, or for use with offset presses.

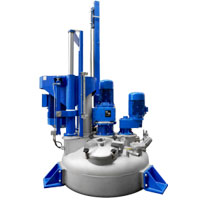

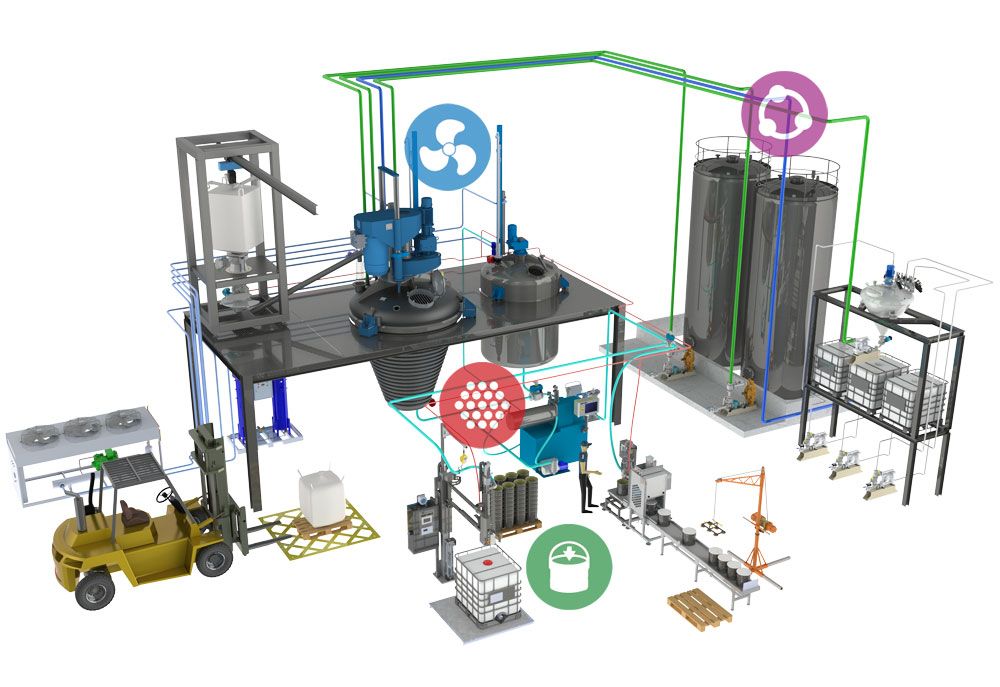

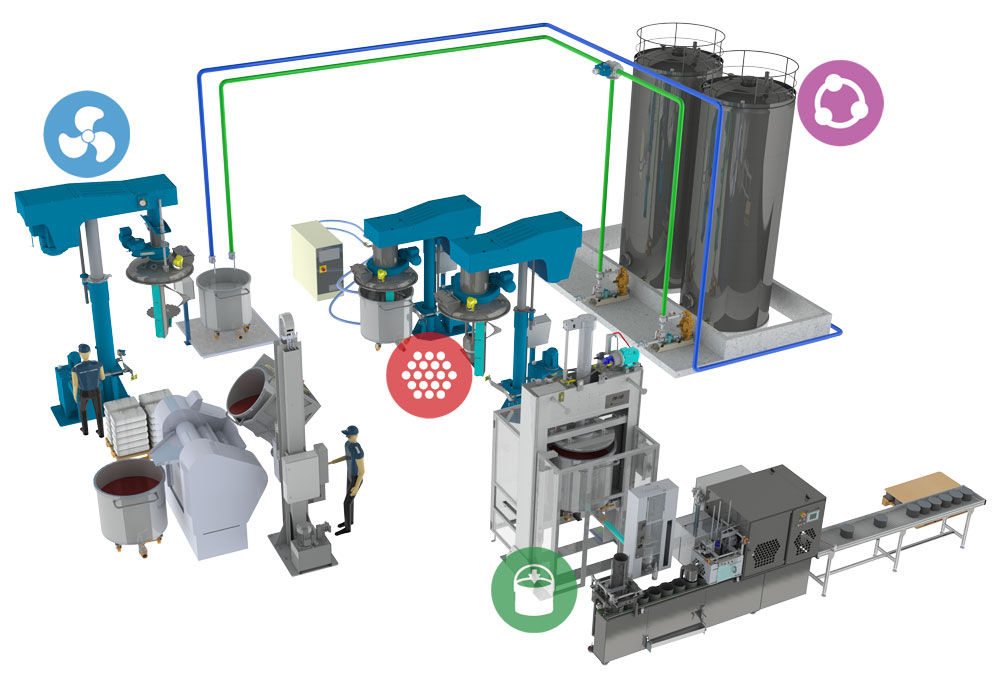

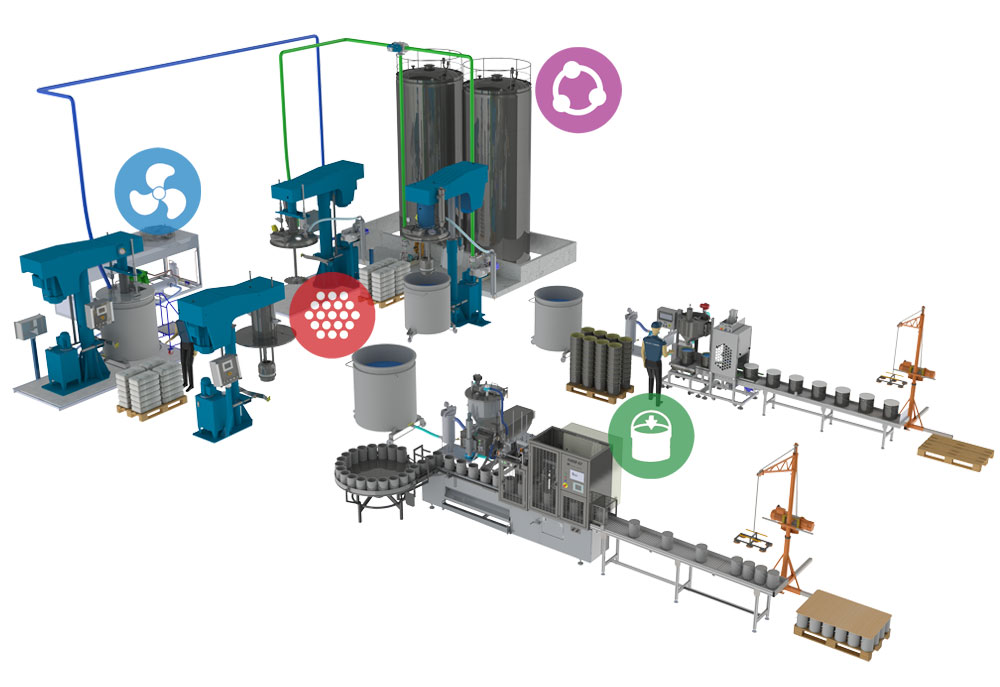

For the manufacture of inks, it is essential to have a production system capable of adapting to very different batch sizes and a filling solution that allows for large-format packaging and yearly batches, as in the case of semi-finished products that are not destined for the end customer.