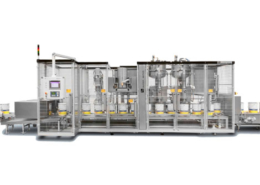

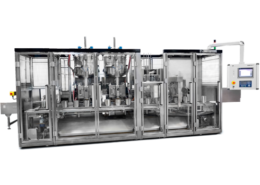

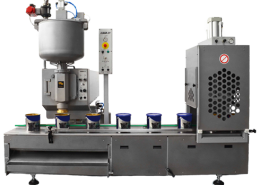

FLASH-53

High output automatic filling line, PLC controlled operation and touchscreen HMI. Conveying table driven by servo-motor, for cans from 50 to 235 mm of external diameter.

Dosage of low and medium viscosity products from 0,1 L to 5 L per stroke and headstock. Lid closing station for flat lids is incorporated into the machine.

FLASH-53-ST model is equipped with 1 dosing head whilst FLASH-53-T incorporates two identical dosing heads.

FLASH-53 range is conceived for high output productions, provided with automatic changeover concerning cconveying table and cleaning cycles.

Advantages

- Integration into a complete filling line, from the pail denester to the palletizing unit

- Automatic format changeover of conveying table and cleaning system, also allowing the creation and edition of recipes

- Double pitch conveying table as an option, to allow the filling rate to be optimized in accordance with can type

- Height adjustment of all the stations by means of a lifting beam

Accessories

- Double pitch conveying table

- Simultaneously adjusted side guides

- Anti-skinning dispenser

- Leak detecting system

- Lug lids closing station

- Automatic container feeding

- Checkweigher with rejection system of containers out of tolerance

- ATEX Certificate for EEx versions

- Other options: Consult us.

Applications

- Paints

- Varnishes

- Glues

- Adhesives

- Liquid Inks

- Others

MODELS / TECHNICAL DATA

| MODEL | OPERATION | FILLING VOLUME | OUTPUT (container /min.) | Nº OF HEADSTOCK |

|---|---|---|---|---|

| Liters | 1 Liter / 5 Liters | |||

| FLASH-53-ST | Electro-pneumatic | 0,1 – 5 | 22-25 / 15-17 | 1 |

| FLASH-53-ST (Double pitch) | Electro-pneumatic | 0,1 – 5 | 28-31 / 15-17 | 1 |

| FLASH-53-T | Electro-pneumatic | 0,1 – 5 | 25-28 / 20-22 | 2 |

| FLASH-23-T (Double pitch) | Electro-pneumatic | 0,1-5 | 31-34 / 20-22 | 2 |