Oliver + Batlle designs paint and related filling equipment tailored to each client considering their needs, product specifications and the characteristics of the production plant. Our industrial filling machines are specially designed to cover a wide range of packages and products with rapid adaptation to different formats.

We design filling equipment for paint, ink, adhesive and putty. Our manufacturing installations projects include pipe cleaning systems (pigging) for a complete solution.

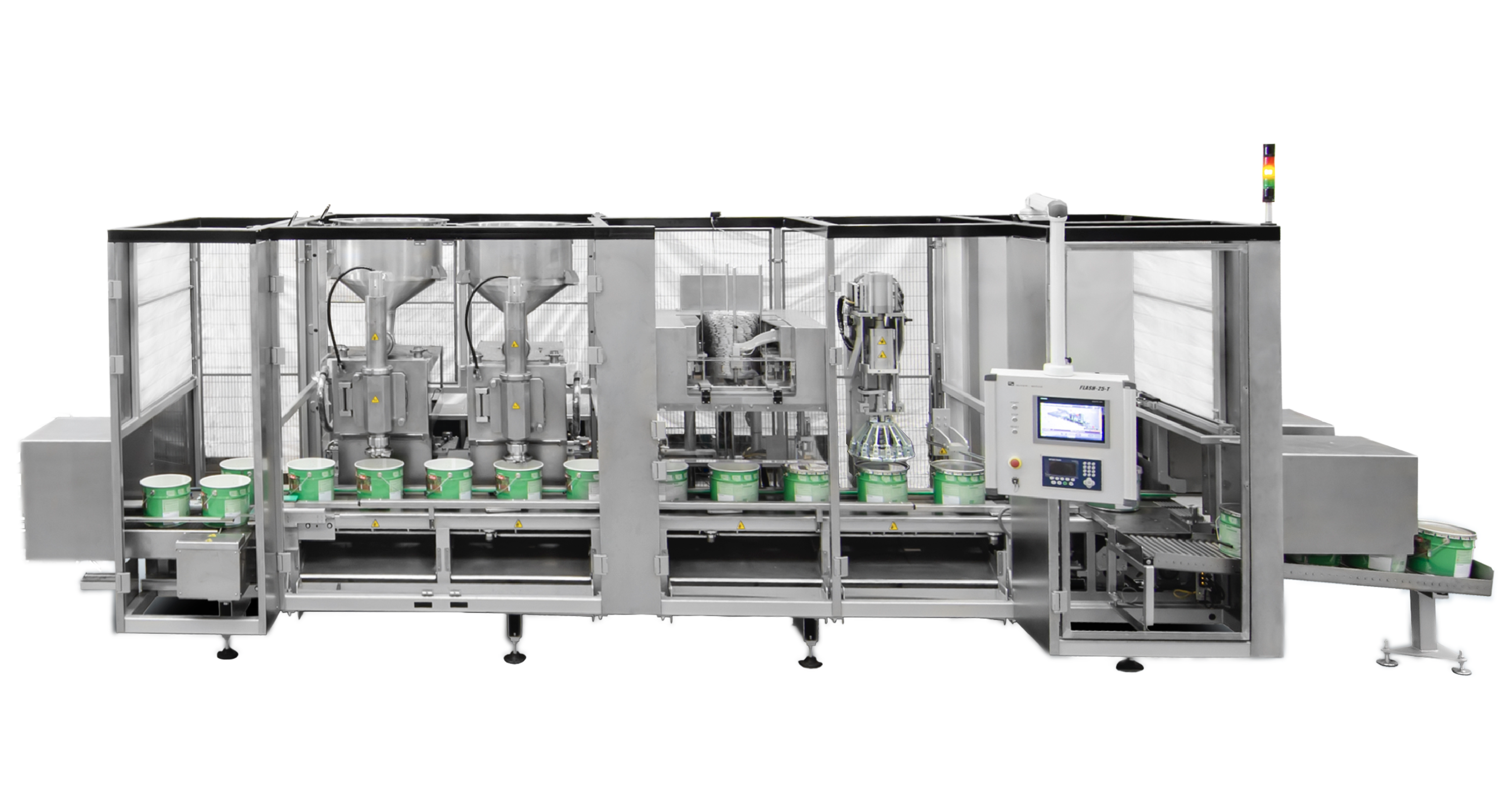

Volumetric filling machines

Our volumetric filling units offer the best solution for volume filling, that is, precision in dosing for medium to high production. We offer semi-automatic filling equipment, such as FLASH 1100, FLASH-50, FLASH-20. We also provide a wide range of automatic industrial filling machines, from the simpler FLASH-51 or FLASH-21 , to the high-tech FLASH-25 and FLASH-55.

Gravimetric filling machines

Gravimetric filling allows the exact calculation of a material’s mass regardless of its fluid conductivity, density or viscosity.

At Oliver + Batlle we manufacture different semi-automatic and automatic industrial gravimetric filling machines. With them we can meet the needs of customers to fill from 100 gr to 1500 k of material.

Semi-automatic filling machines OB-15/30, OB-130 and OB-1300 are easy to use and include weighing systems for small production. They are the perfect solution when flexibility is the most important parameter in the process.

The COMBI-6 and COMBI 130 automatic filling units are equipped with weighing systems for medium outputs, with the possibility of integration into a complete filling line, from the pail denester to the palletizing robot.

High Viscosity Filling Machines

This range of filling machines is recommended for the filling of high viscosity products into containers and cartridges. They allow dosing by volume or weight depending on required accuracy. We offer units for packing putties, presses, hydraulic caps and dispensers.

Presses and hydraulic lids such as the PH press and PCH-TVH press lids can be used in the manufacturing of pasty products of medium and high viscosity, by means of hydraulic presses, capable of extracting the entire product from the manufacturing tank itself.

DV Dosers are primarily used for filling putties and products of medium or high viscosity and low or zero fluidity.

The combination of the FLASH filling lines, with the PH Presses and DV Dosers, allows the creation of EM filling lines for putties.

Pail Denesters

At Oliver + Batlle we manufacture packaging handling solutions, as a complement to our range of gravimetric and volumetric filling machines. Our equipment can handle all types of containers used in the paint industry.

In our range of pail denesters, we offer PAILMANAGER V-FLEX, PAILFEEDER and DPT-130.

Automation of industrial filling machines

Automation processes have an impact in the reduction of operating costs, accidents and losses, and contribute to avoid wasting material and to increase profits. The main advantages of automation are:

- Machines with 100% automatic format change.

- Machines that store all operating variables such as volume or weight to be filled, dosing speed, transport speed, verification of filling quality, control of imperfections, etc., and implement them without any intervention by the operator.

- Fully automated dispenser and hopper cleaning systems with hygienic design.

- Palletising and pallet entry management to the finished product warehouse.