In Oliver + Batlle we offer a wide range of mixing equipment for all types of paints, coatings, dyes, inks, adhesives and putties.

We offer mixing and dispersion equipment for manufacturing low, medium and high viscosity products at a laboratory and industrial scale.

Dispermix VF-L

Batches from 0,1 to 150L.

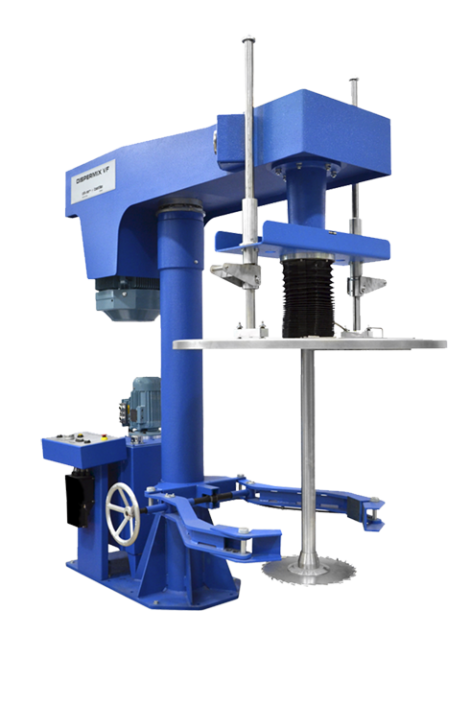

Dispermix VF

Portable vessels.

Dispermix VF-E

Dispermix Dual VFD

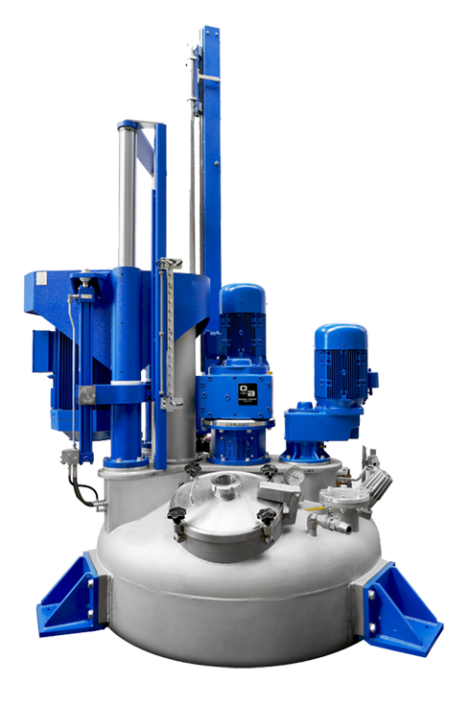

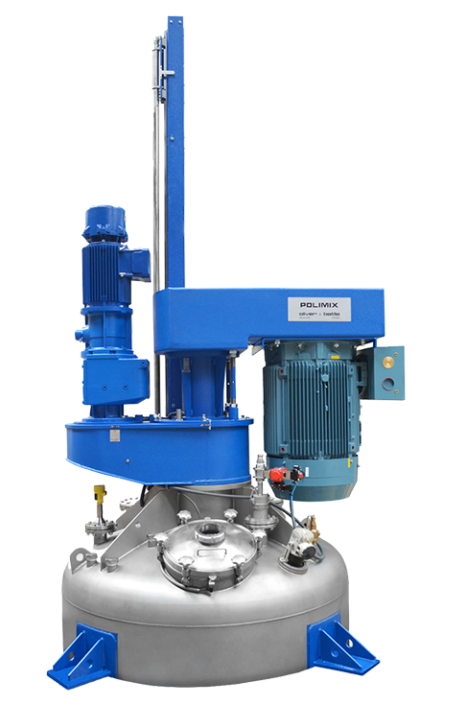

Polimix DPS

Polimix DPS-OR

Hidrobat Planetary-Mixer

Finishing Tanks TA

Batches from 1.000 to 20.000 L.

Industrial mixing machines

The industrial dispersers of Oliver + Batlle are designed for mixing paints and other types of liquids of different density , guaranteeing homogeneity and viscosity according to customer needs. Our machines stand out for their robustness and reliability in design.

Oliver + Batlle mixing equipment are mainly used in the manufacture of decorative paints, varnishes, industrial coatings, glues, adhesives or liquid inks among others.

In Oliver + Batlle we work to always offer the latest innovations in mixing equipment. Our main aim is to achieve the highest efficiency and versatility in industrial technology. The Polimix disperser machine allows great adaptability in its functions.

Among industrial mixers for medium or low viscosity paint, Dispermix models are the most notable in their varieties VF for portable vessels, VF-E to be mounted on platform, VF-L as laboratory version, and Polimix DPS-OR. As for high viscosity agitation machines, we highlight the Dispermix Dual VFD, Polimix DPS and planetery mixers Hidrobat. We also produce finishing tanks for mixing and finishing of paints and coatings.

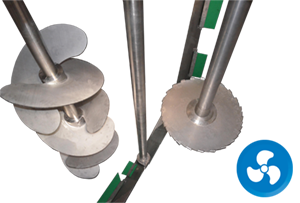

Components of Industrial Dissolvers

At Oliver + Batlle we are always alert to the needs and trends of the market and we apply our knowledge, experience and innovative technologies to the implementation of solutions for agitation, mixing and dispersion of paints and other products.

This state-of-the-art expertise allows us to manufacture industrial agitator machines that ensure a homogeneous finish, enhancing the mixing between the different particles that make up each product.

Advantages of Oliver + Batlle mixing solutions

Our agitator machines have a large number of advantages depending on the model and the purpose for which it has been designed. However, the following advantages are common to all of them:

- Easy installation in plants for manufacturing decorative paints, industrial coatings, marine paints, glues, varnishes, adhesives, inks, etc.

- Simplicity of use in processes that require a high speed of mixing or dispersion.

- High durability components.

- Increased productivity in allowing simultaneous processes.

- Wide range of mixing equipment with high efficiency in the dispersion and agitation processes of paints, inks, adhesives and putties.

Services and assembling of mixing equipment

In Oliver + Batlle we specialise in the manufacture, assemblage and installation of mixing equipment.

Our team of professionals provides integral advice according to the needs of each client, guiding the choice of the best solution and achieving the expected results in the final product.

We offer, in addition to the best technical solutions available in the market, a series of after-sales services that allow us to extend the life cycle of our machines. Thanks to our technical support, our mixing equipment is always as good as new for we supply spare components and coordinate an agile and efficient technical service internationally.

Explore the wide range of Oliver+Batlle mixing equipment