Oliver + Batlle grinding equipment offer fine quality, transparency, gloss and pigment development in the manufacturing processes of paint and ink.

All milling equipment is specially designed to meet any needs in terms of product processes and operations in the manufacture of paint, ink and putty.

Grinding equipment

The Oliver + Batlle grinding equipment is versatile and allows to regulate the movement and the force produced in order to properly combine the components. This results in homogeneous products with the set final texture, in accordance each costumer’s specifications.

Our milling technology combine grinding and dispersion functions. This contributes to reduce the size of particles in all kinds of grinded emulsions for paint, coatings and ink.

Batch – Immersion milling

Our batch milling technology make wet pigment dispersion with basket mills that allow to manufacture products with a very uniform particle distribution and colour development.

Batch milling avoids the use of pumps and pipes, saving time and energy, and making the process cleaner.

Our Mill-ennium RS immersion mill is especially suitable for the manufacture of decorative and industrial paint, dye and liquid ink among other products. For laboratories, Micromill-Pilotmill immersion mills also use the batch procedure for manufacturing low and medium viscosity products.

The immersion grinding equipment has a number of advantages compared to other available technologies, it:

- reduces waste

- is easy to use

- lowers maintenance costs

- takes less space

Continuous milling

The continuous process is the most widespread for all kinds of grinded emulsions for paint (decorative, industrial, marine, etc.) and in general for medium and low viscosity products. Our Supermill EHP is the most flexible solution when the batches to be processed vary greatly in volume.

Recirculation milling

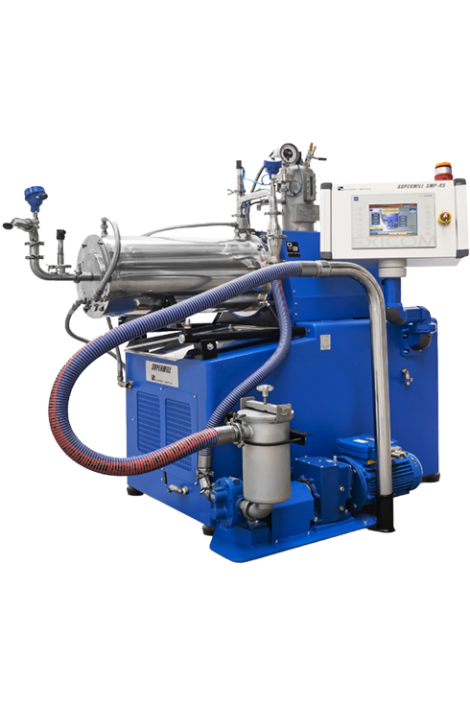

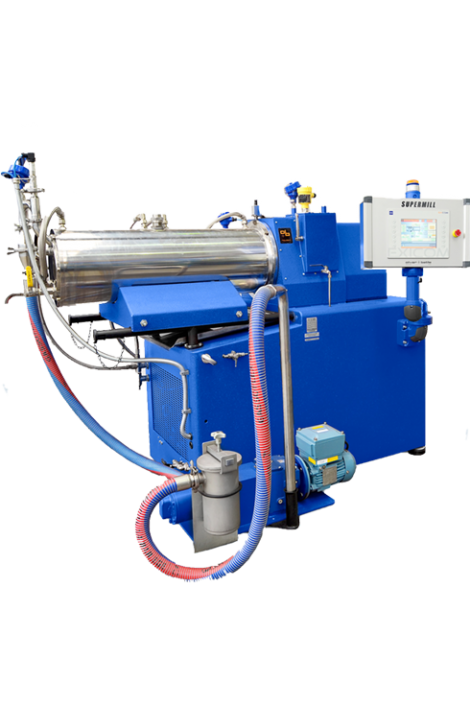

The grinding equipment Supermill Plus, a horizontal recirculation mill, has been designed for high energy and density grinding processes. It can be used for manufacturing decorative and industrial paint, varnish, metal paint, liquid ink, marine, aeronautical and automotive paint and phytosanitary products.

GRINDING EQUIPMENT DEVELOPMENT

In Oliver + Batlle we are specialists in the assembly and installation of grinding equipment. With our technology we develop different milling systems to achieve the fineness, transparency, brightness and pigmentary development that each client needs.

We provide our clients with specialised personnel to help define the most appropriate machinery and its operating parameters.

Automation of milling equipment

Depending on the operational needs of each client, in Oliver + Batlle we can automate the grinding process. For this, we offer the following control systems:

- S : Control system with electric keypad, allows manual operation of the equipment, and optionally the control of the process by time or consumption.

- CP : Digital signals + Software + Touch screen, allows management and operation with manufacturing recipes, machine set-up, operation supervision and maintenance monitoring. The visualisation of all the process parameters reduces downtime, facilitating the autonomous work of the machine, with an alarm system for any incident.

We adapt to the needs of our customers to create a functional set of equipment of the highest quality.