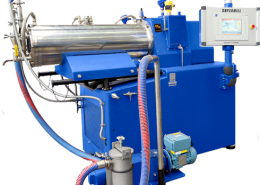

Mill-ennium RS

Small ratio basket volume / product volum to be processed , positionning the range of immersion mill models Mill-ennium RS as the most efficient in the market in terms of process time, total power consumtion, consumable cost, and total operative cost .

Portable vessels with double cooling jacket at side and bottom.

Micro ceramic beads of high density to obtain size particle homogenous at the shortest period of time.

RS basket mill can process low, medium and high visocisty products.

Advantages

- Reduction of losses.

- Short process time

- Fast cleaning, minimum power consumption

- Size particle between 1 and 5 µ

- Scraper blade to improve the heat exchange.

- As an option: Orbital blade with helix to improve product flow (high viscosity)

- Available for ATEX Zone 0

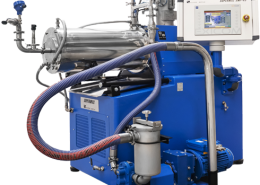

Accessories

- Telescopic lid

- Vacuum lid.

- Orbital scraper blade to improve heat exchange.

- Orbital scraper blade with helix, for high viscosity products.

- Control system options:

- Version S (standard pushbuttons)

- Version CP (digital signals + software + touch screen)

Applications

- Decorative paints

- Industrial Paints

- Automotive Paints & Coatings

- Can – coil coatings

- Colorants

- Liquid inks

- General use for grinding purposes in low and medium viscosity.

MODELS / TECHNICAL DATA

| MODEL | GRINDING CHAMBER VOLUME (L) | POWER (kW) | VESSEL | BATCH (L) | VESSEL | BATCH (L) |

|---|---|---|---|---|---|---|

| Small batch | Min / Max | Big batch | Min / Max | |||

| RS-1 | 1,6 | 7,5 | DH-45 | 20 / 45 | DH-85 | 50 / 85 |

| RS-2,5 | 3,3 | 11 | DH-90 | 45 / 90 | DH-200 | 100 / 200 |

| RS-5 | 6,6 | 18,5 | DH-160 | 90 / 160 | DH-400 | 220 / 400 |

| RS-10 | 11,8 | 30 | DH-300 | 170 / 300 | DH-800 | 430 / 800 |

| RS-20 | 26,6 | 45 | DH-600 | 350 / 600 | DH-1300 | 790 / 1300 |

| RS-30 | 35,8 | 55 | DH-1000 | 525 / 875 | DH-2200 | 1180 / 1960 |