Paint manufacturing equipment: information & news

In Oliver + Batlle we are specialists in the design of equipment and integral solutions for paint manufacturers. We have created this section in our website where we want to provide relevant and quality information about paint manufacturing equipment.

Innovation, new technologies and environmental sustainability are the three main lines that guide the development and evolution of production systems. In this sense, through our blog we want to echo all those news, innovations and trends that occur in our sector.

We invite you to participate through the comments enabled in each article, contributing with your opinion or sharing with our community any doubts, consultations or releases of interest about anything.

Read all our Oliver+Batlle blog articles below.

![]()

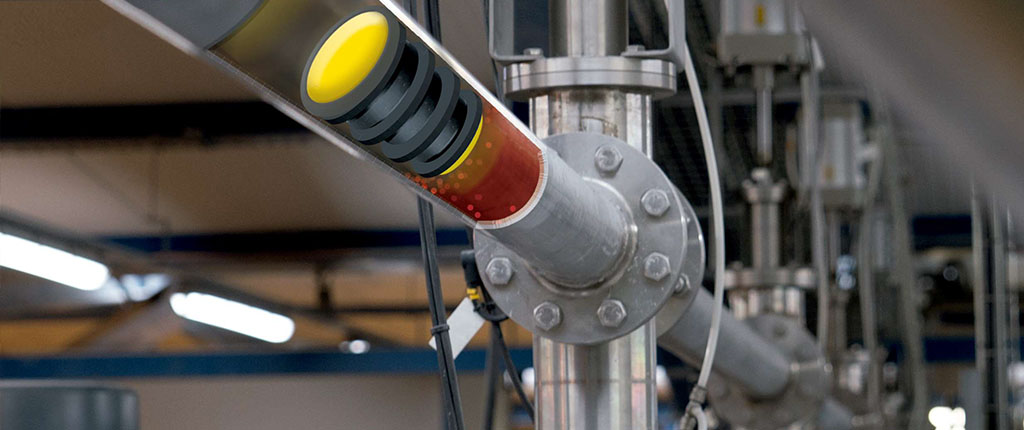

Oliver+Batlle, PAINT MANUFACTURING EQUIPMENT SPECIALISTS

In Oliver + Batlle we work to offer the best solutions in paint manufacturing equipment. Our services: technical service, sale of components or our test laboratory for the manufacturing equipment, allow us to maintain a direct and constant contact with our clients. Thanks to this, we are able to design equipment adapted to each manufacturer specific needs.

With over 60 years of experience in the sector and our know-how, we are in O+B at the forefront of creating solutions and manufacturing equipment for the paint production. Our mixing equipment, grinding machines, filling equipment, accessories and other solutions for the paint industry are constantly updated. We introduce new features looking for the excellence in performance and optimization of the productive work of our customers.

In this section we want to share all the news, updates and information about paint production equipment, clarifying doubts and providing knowledge and valuable information to the sector.